The rotary feeder is a device designed for receiving and dispensing loose and fine materials. It can be used as a closure for bag filters, silos and cyclones. The material is poured through the feed pipe, then the material is dispensed via a rotating rotor with blades. The material leaves the dispenser through the discharge port.

Rotary feeders are installed under silos, transport devices, filters and cyclones as well as in pneumatic transport installations. We produce rotary dispensers with high operating parameters, tailored to the needs of our customers. Turned parts are prepared on numerically controlled machines, welding takes place on automatic lines, and finished products are painted in a painting and drying booth, guaranteeing high quality protective coatings.

Rotary feeders are widely used in industry. Technological installations for transporting bulk materials, from granulates to the dusty fraction of the material, require the use of rotary feeders in the transmission, dosing or storage processes. Rotary feeders are installed under silos, transport devices, filters and cyclones as well as in pneumatic transport installations.

Biko Tech manufactures rotary feeders with high operating parameters, which are always tailored to the needs of our customers. For many years, the company has been providing services in the field of maintenance and supervision of rotary feeders in existing technological installations, which gives us a wide range of knowledge about rotary feeders and the specifics of their operation. This in turn guarantees the selection of the most optimal solutions in the devices we manufacture.

The selection of rotary feeders is carried out individually on the basis of collected information about the technological process, efficiency and type and properties of the transported medium. On this basis, it is possible to determine the type and size of the offered rotary feeder as well as the material configuration of the body, side covers and rotary wheel. It is also possible to make a rotating cell in the material configuration specified by the customer.

Our feeders have a certification as a protective element in explosion isolation systems (Directive 94/9/EC, EN 15089). Rotary feeders are mounted under silos, transport devices, filters and cyclones as well as in pneumatic transport systems.

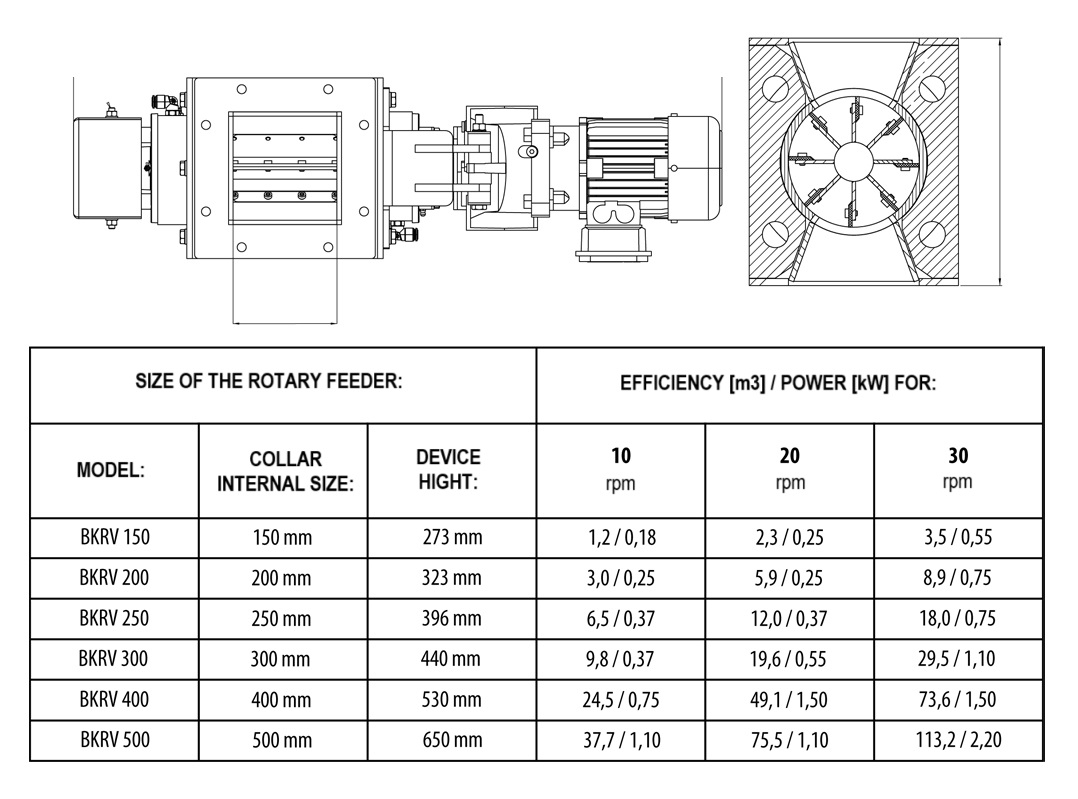

The operating principle of rotary feeders is very simple. Each rotary feeder consists of a cylindrical chamber in which a rotor rotates, which has, depending on the situation, 6 or 8 chambers feeding the material. The rotor is driven by a gear motor.

Material feeding through the rotary feeder is a fully adjustable process, it can work intermittently in the case of dosing or continuously in the case of transporting material / raw material. By regulating the speed of the gear motor, we influence the efficiency of the rotary feeder process. At slow speeds, we feed / transport less material, while at higher speeds we feed more material.

Depending on technological needs, the bodies of rotary feeders can be made of black steel or stainless steel. Sealing plates are screwed to the rotor blades, which can be made of polyurethane, silicone, rubber or, if necessary, other plastics. These vanes and side discs are replaceable sealing elements of the device.

The inlets and outlets of the rotary dispensers are finished with special connecting flanges, which can be round, square or rectangular. It is possible to drill the inlets and outlets according to the customer’s guidelines.

The temperature of the material dispensed in a standard rotary dispenser should not exceed 80 degrees Celsius. At higher temperatures, we offer rotary dispensers in a special version. For installations installed in explosion hazard zones, rotary dispensers with the ATEX certificate are used as equipment or as protection against the effects of an explosion, i.e. against a sudden increase in pressure and as protection against the penetration of flame.