We advise, design and produce process tanks and process reactors made of black, stainless, acid-resistant and wear-resistant steel – individually tailored to the production profile of our clients.

Depending on the process, we choose the type of tank, dimensions, accessories and automation to make the process taking place in the tank more efficient and repeatable. Our experts in chemistry and engineering have specialist material knowledge and excellent knowledge of your processes, thanks to which they are able to design all devices in compliance with the strictest safety rules.

Process tanks take part in industrial processes and are used to process products. Their main role is to ensure reliability and meet the conditions required by a given production technology. Process tanks are specialized devices and the main difference is that they are not storage tanks.

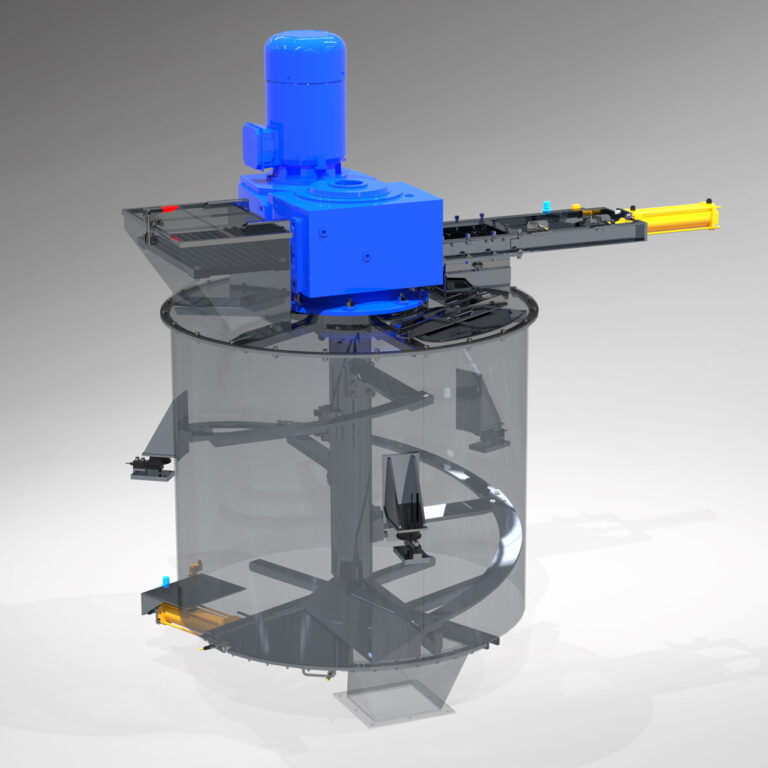

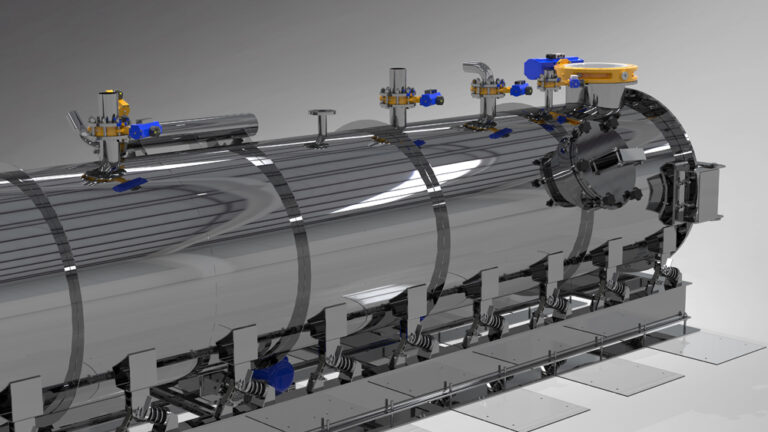

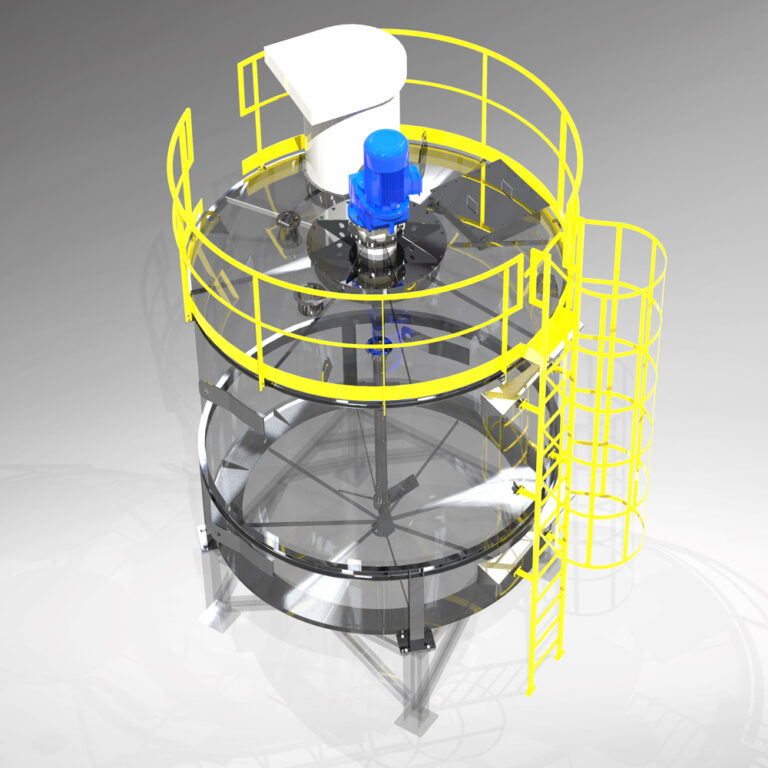

Depending on the type, they are used to carry out processes, mixing or processing liquid and loose substances. Its design is adapted to work in specific conditions, such as high pressure, high temperature or corrosive environment. Depending on the needs and specifications of the production process, these tanks come in various sizes and shapes. The design and equipment of the process tank depends on the function it performs on a given line. We produce both technological tanks in the shape of a vertical cylinder, as well as cuboidal tanks, sometimes with a non-standard shape.

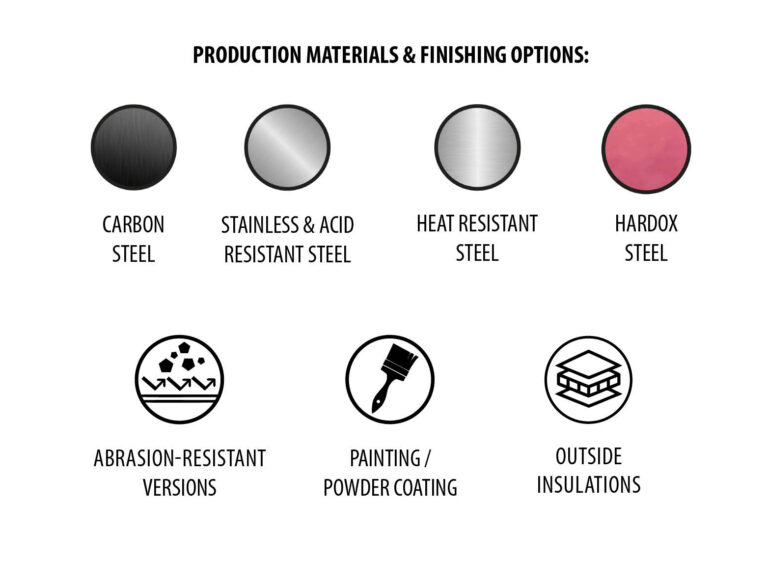

One of the key parameters influencing the construction of the process tank is the material from which it is made. Choosing the right material is extremely important because it affects the strength and durability of the tank. Depending on the operating conditions of the tank in your plant resulting from the production process, technology, specificity of the chemicals used, temperatures, heat dissipation inside the process tank, pressures and concentrations prevailing inside, etc. for stable process conditions. Therefore, we will select appropriate production materials that are resistant to the above-mentioned factors. This will ensure a reliable and correct process.

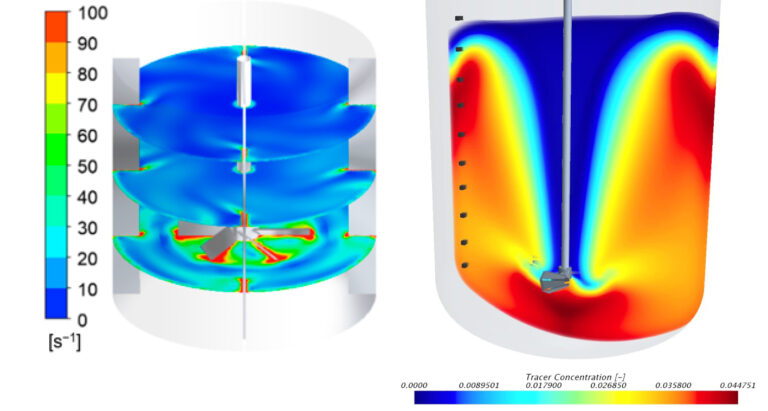

As a result of constant development, digital simulations of processes in DEM and CFD technology, research and innovation as part of R&D projects, we are a leading manufacturer of process tanks on the European market. We are also open to various types of modifications.

We offer the construction of sterile process tanks intended for contact with food and fermenters. For processes used in the food and pharmaceutical industries, such as pasteurization and fermentation, heating and cooling of the tank is crucial. Proper connections to the tank insulation must be ensured so that heating and cooling of the product occurs at the appropriate time intervals. Please let us know directly what features you need. Together we will develop the most effective solutions, such as the use of a heating/cooling jacket, double walls or half-pipes.

Process tanks include: chemical reactors, mixers of corrosive chemicals with a conical or flat bottom (variant with a structure supporting a mechanical stirrer), devices for reducing the chemical charge, devices for dosing chemicals, coagulants, acids and alkalis.

Let our engineers find the best solution for the optimal combination of functions such as mixing powders or liquids, appropriate pressure, heating/cooling of substances. Our Engineering Department and production department can adapt tanks to the most demanding and rigorous standards. At the customer’s request, we can create tanks with much smoother (more hygienic) internal walls.