Quality control of production processes, as well as testing the quality of final products, is necessary to maintain the repeatability and quality of manufactured substances. Cyclic sampling of raw materials carried out using sample collectors during production is necessary to conduct laboratory analysis of the characteristics of the sampled material. Based on the results of quantitative and qualitative tests of the substance, the quality of the tested sample is determined and, in the longer term, a decision is made whether a given batch of the product meets specific requirements and standards, and whether any corrections to the production process should be made.

We are specialists in the field of bulk materials, so we offer the best solutions for sampling in pipelines, transfers and storage tanks (e.g. for grain, flour, other powdered and loose chemical substances)

The collected samples are collected in special packaging / jars whose mounting stubs or threads are specified by the customer.

Sample collectors are designed to work in many industries: food, chemical, cosmetics, pharmaceutical, cement, refinery and others.

Sampling is therefore key to obtaining accurate test results. Other aspects include reliable storage and transport of samples, ensuring a proper chain of custody. Without appropriate sampling methods, the results of even the most thorough and precise samples will not reflect reality.

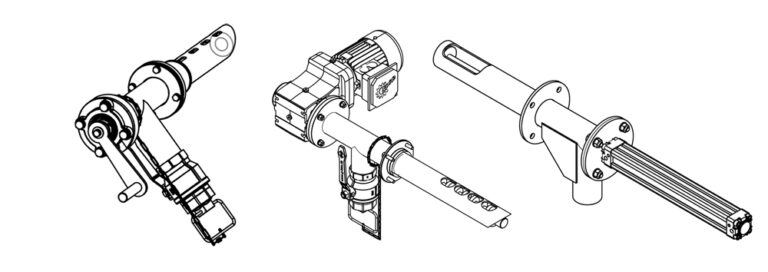

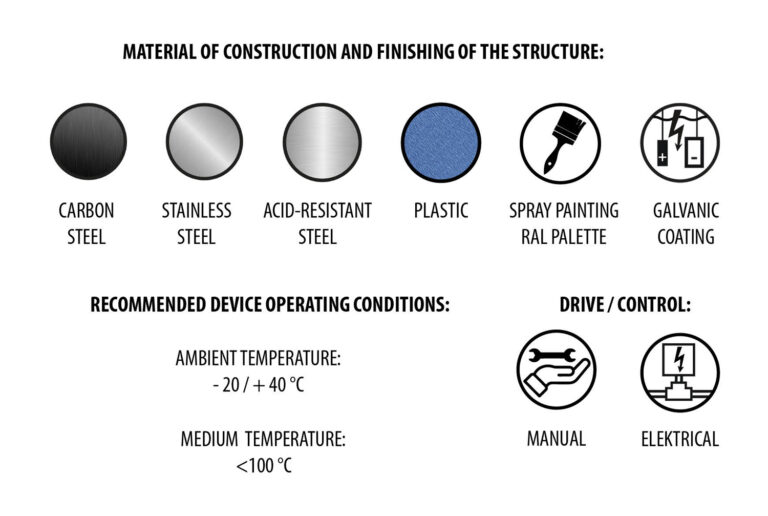

Sampling of bulk materials can be carried out in various ways, depending on the type of technological process and the type of material to be sampled. At the moment, two main categories of sampling can be distinguished: manual and automatic.

The latter is usually carried out using electrically powered devices. Each of the mentioned options has advantages and disadvantages, it is worth considering which method to choose for your own technological line.

Manually downloading materials is certainly the cheapest solution, although it is also not the best solution and, paradoxically… cheap. Why? Manual sampling requires the operator to stop production and restart the entire production installation. Manual sampling therefore requires downtime, which generates significant costs in the production process.

However, an automatic sample collector (appropriately selected for a specific application) is a solution that eliminates the costs of generating production line downtime and reduces the risk of an accident at work. The representativeness of the sample and the reliability of laboratory test results are also significantly increased in this case.

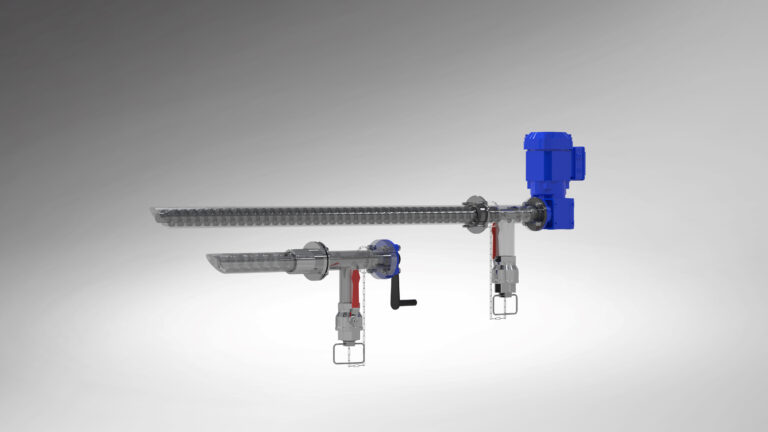

Automatic and maintenance-free sample collectors produced by Biko Tech can be installed both in storage tanks, buffer tanks, hoppers, and less frequently in pipelines, mainly in chutes and dumps. The control system has electronic regulation of the sample collection time and the time interval between subsequent collections, which allows for precise selection of the sample size and frequency of its collection.