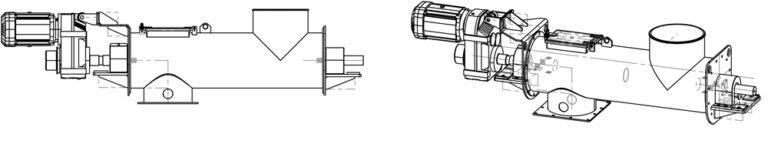

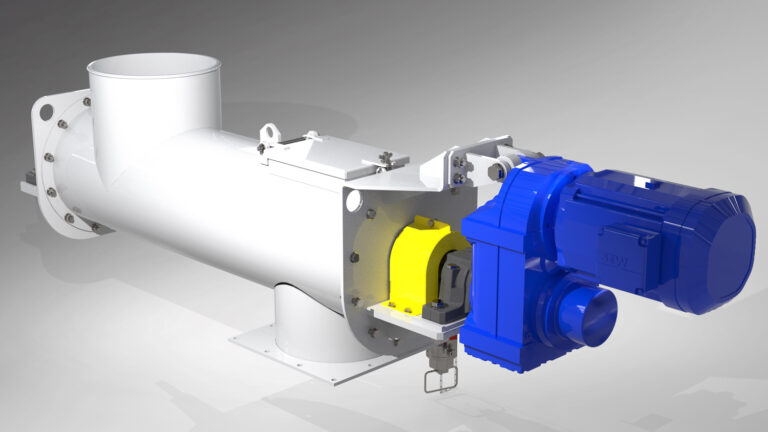

Screw dispensers ensure continuous (flow) dosing of bulk materials (especially powders and granules) with an accuracy of 1-3%. Screw dispensers are perfect for installations requiring simple, effective and dust-free solutions. When it comes to variants, these devices can be: single or double shaft, trough or tubular.

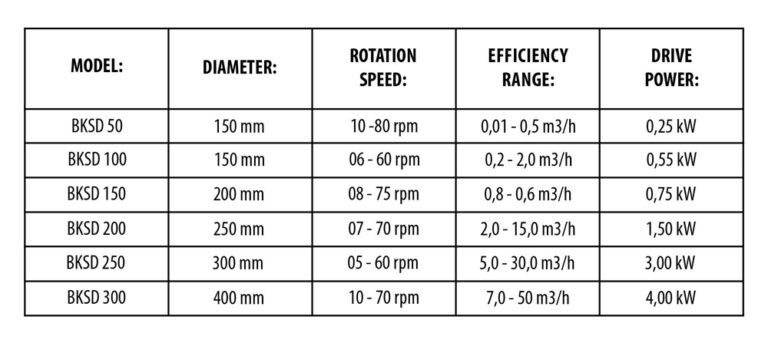

The features of our devices are high efficiency with small diameters, high throughput, easy installation and durability.

Depending on the characteristics of the material being dispensed, different models of screw feeders are available for different applications. These devices have a very wide range of uses. They are used to dose a wide range of bulk materials: from cement, through fly ash, filler dust, silica dust, plaster, sand, calcium carbonate, sand, to cereals and sawdust. They are used, among others, for feeding and conveying cement and fillers in the production of concrete, cold fillers and asphalt, as well as for transporting cement and other types of materials in the construction industry.

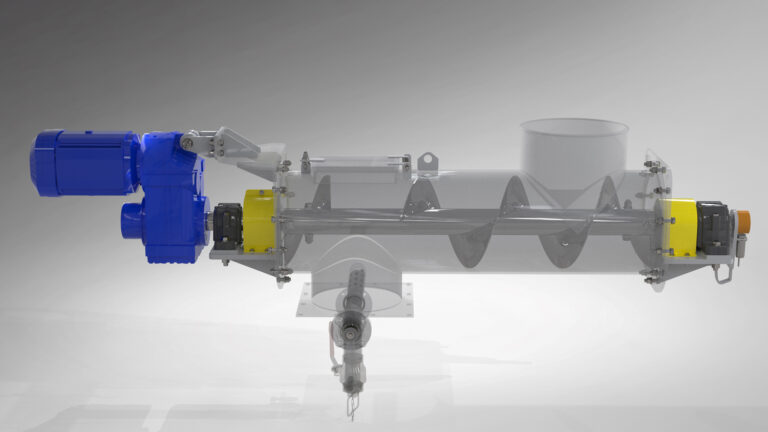

BKSD screw dispensers manufactured by Biko Tech are used to transport and precisely measure the amount of loose products, e.g. for ready-made packaging using the volumetric method or separate packaging devices installed in the technological line.

BKSD screw dispensers can also be used to dispense granulated materials, creating a precise mixture of the material and some component (e.g. dye concentrate). High accuracy is achieved thanks to frictionless articulated support in the feed axis and separation of the device from external forces.

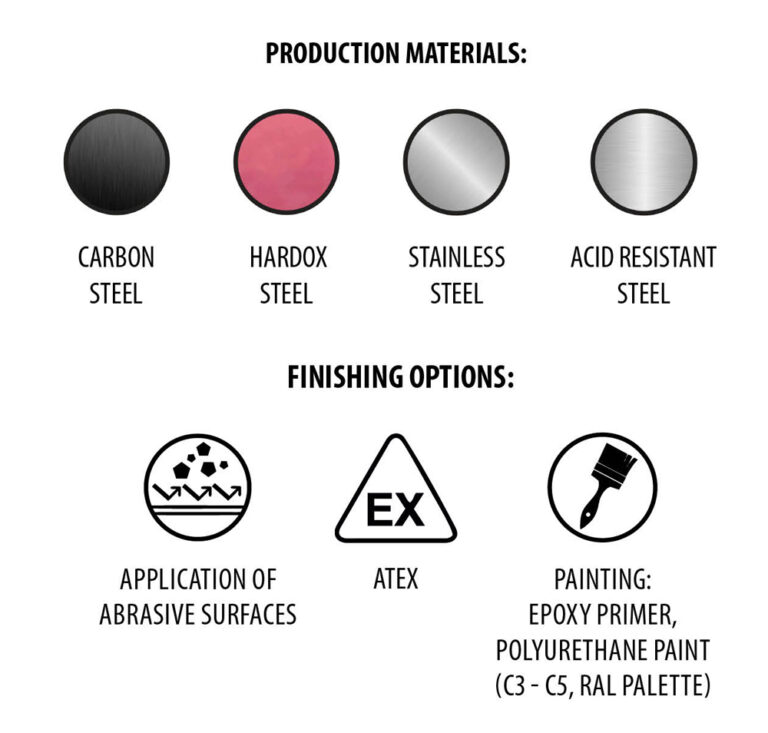

Screw dispensers manufactured by Biko Tech are precise, reliable and universal dosing devices. We can make these devices on any scale, regardless of the size and efficiency of the device, the dispensers are always easy to operate. Smooth regulation of dosing efficiency throughout the entire operating range of the device and stability of engine speed guarantee repeatability of the determined performance. Our devices are equipped with dedicated controllers with analog and digital communication in various data transmission modules. The control can be automatic, where the rotational speed of the dispenser is synchronized with the existing technological line. It is possible to adjust the efficiency of the screw dispensers we produce by changing the geometry and internal dimensions of the device. Screw dispensers produced by Biko Tech are easy to clean and maintain. Reliability, the highest quality production materials, innovation, efficiency, durability and professional technical support are the distinguishing features of Biko Tech screw dispensers that operate effectively on almost all continents.

Our devices are equipped with dedicated controllers with analog and digital communication in various data transmission modules. Control can be automatic, where the feeder’s rotational speed is synchronized with the existing technological line. It is possible to correct the efficiency of our screw feeders by changing the screw design. Biko Tech screw feeders are characterized by the possibility of easy cleaning and maintenance. They can be single or double shaft, trough, tubular trough, screw, screw.