In the broadly understood industry, shredding machines play a very important role. Whenever lumpy agglomerates, compressed materials, lumps of raw materials, plastics, metals and scrap, as well as, for example, frozen food products need to be crushed in industrial processes, crushers and shredders are implemented. Crusher machines are successfully used to reduce the volume of various large-sized production waste by cutting and shredding them. The devices are designed to crush material lumped during storage before further processing or transport.

Shredding machines are used in various industries, such as: construction, carpentry, pharmaceutical, food, mining and aggregates, paper, metallurgy, waste recycling and raw materials recovery. Increasing efficiency as well as streamlining some processes related to broadly understood processing is one of the most important tasks, which is carried out thanks to properly matched shredding machines.

The Biko Tech company comes from the cement and lime industry, so we have the greatest experience on the market in designing shredders used at the outlets of bulk materials from tanks, e.g. cement, ash, flour and lime silos. The crushers and shredders we offer can be used to perform the most difficult tasks, ensuring adequate process efficiency and intensive work with low electricity consumption and low operating costs.

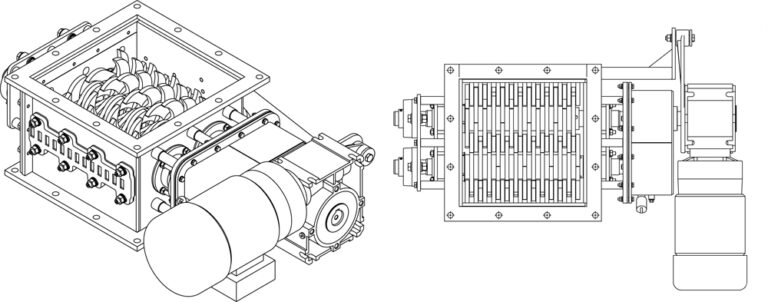

Thanks to the modular type of construction, lump crushers produced by Biko Tech can be seamlessly integrated into existing production lines or work as separate, free-standing devices. Our structures are characterized by high stability, durability and are devoid of the so-called “blind spot”.

Large inspection holes allow for easy and quick cleaning and maintenance of the lump crushers. The new version of the shredder is easier to use – it allows you to replace the knives without dismantling the entire device. The devices are specially hardened depending on the type of agglomerate being processed. Lumpy and hardened bulk materials are transported by gravity through the inlet to the lump crusher. The rotating rotor knives force the product through the grinding sieve and grind the agglomerates to the desired final grain size. Our devices are exceptionally well sealed, which ensures failure-free operation also in a continuous system.

Our solutions are based on the results of simulations of the actual behavior of bulk and lump materials using the discrete element method (DEM). We are one of the few European companies that use DEM capabilities when designing devices. Thanks to this, we can boast the highest energy consumption.

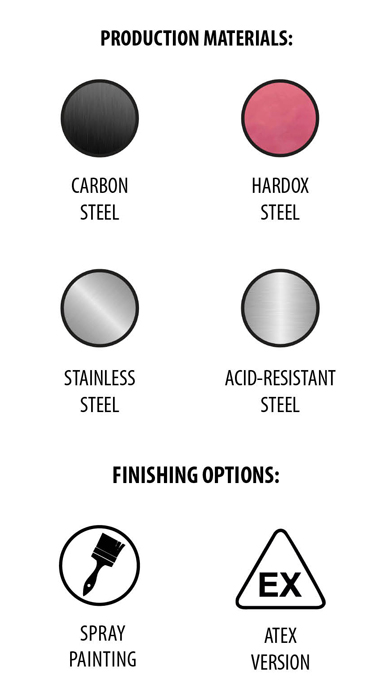

All our shredding machines are made of the highest quality materials and components, which guarantees their durability and failure-free continuous operation. We also attach great importance to the way they are made – we primarily want the devices offered by Biko Tech to serve our customers as long as possible.

The initial products subjected to the grinding process may be: dry, brittle or slightly moist. Depending on the use of shredders, different varieties and versions are used: we individually adjust the sizes of flanges and outlets, meshes stopping too large material fractions, engine power, number of drive shafts, types and strength of drive gears, material of the cutting system, sealing of devices and also the overall size of the devices and their total weight. The ergonomic hopper of the shredders is designed for manual or mechanical loading via a loading conveyor. The hopper can be equipped with dust removal channels necessary for shredding. We are able to offer equipment completely tailored to the individual needs of our Clients.

BKLC shredders are solid structures, adapted for continuous operation. High efficiency and low frequency of replacement of consumables make the operation of the devices very convenient. BKLC shredders are entirely manufactured in Poland, using the highest quality components, which guarantees that there will be no problem with access to service parts for a specific machine, as well as subsequent modernization of the selected model.