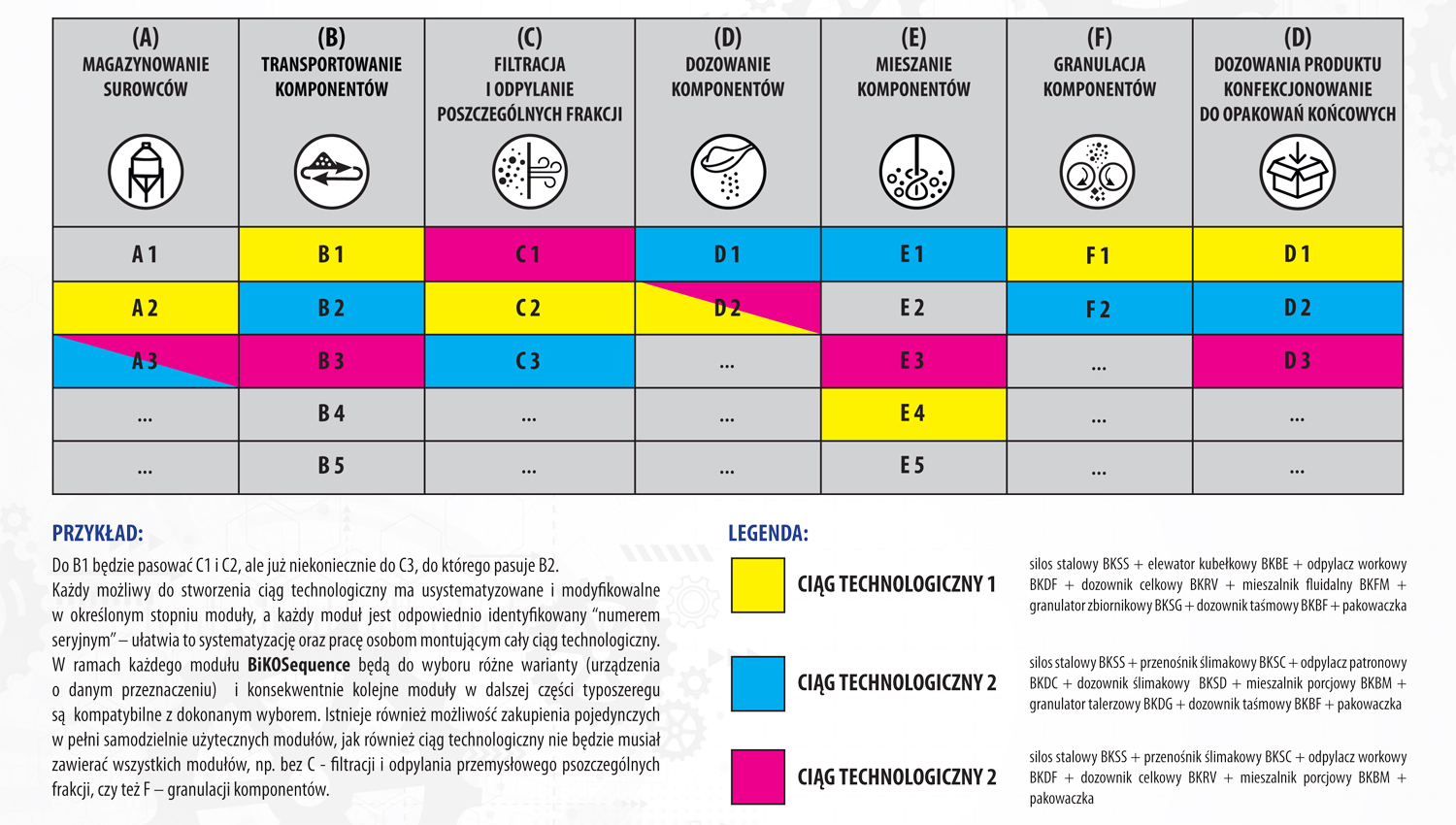

The idea of the BiKOSequence program is to implement a series of fully compatible industrial devices for the processing of bulk materials, designed and manufactured entirely by Biko Tech.

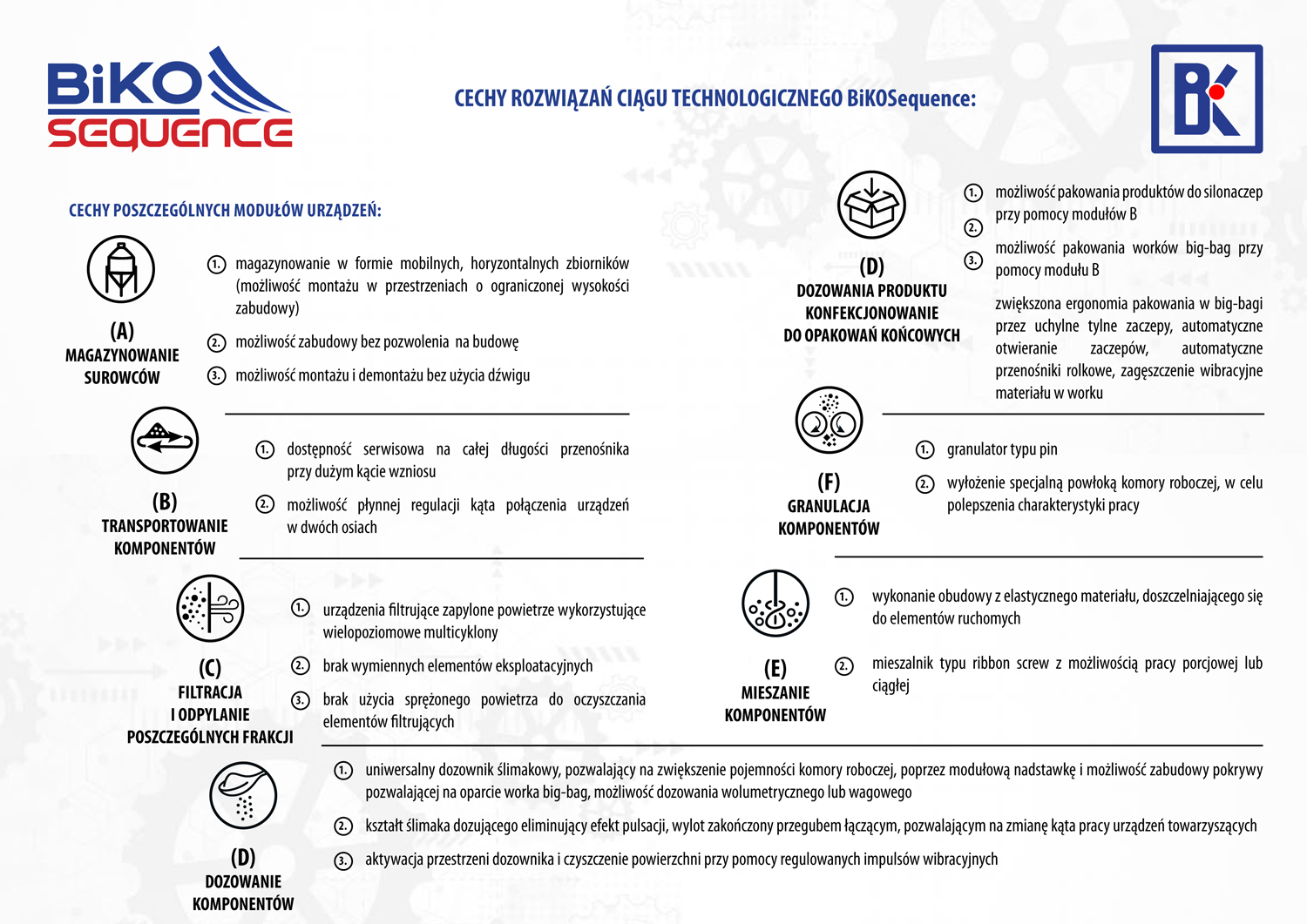

As part of the business of manufacturing machines and devices for the cement and lime, chemical and food industries provided by Biko Tech, we present the BiKOSequence program, which is a modular technological series, i.e. a series of standardized, ready-made devices, designed for: storage, transport, filtration, dosing, mixing, granulation and packaging of bulk materials) with defined features and parameters.

The presence of ready-made modular solutions in the Biko Tech offer (without the need to design and manufacture them from scratch) meets the needs of our Clients who, in addition to individualized projects, are also looking for ready-made solutions for quick implementation in their companies. Shortening the waiting time of the Client for the production of the ordered machine or device reduces the share of factors creating additional costs in the process of service provision (searching for solutions, analyzing the possibilities of adapting the new device to the devices already owned by the client, making the project, ordering materials). Repeatability of production and cataloging of devices also facilitates the provision of service services by the company, which currently require the production of each part from scratch. The functionally and stylistically coherent set of devices forming the BIKOSequence technological line is also the technological showcase of Biko Tech.

Standardized and compatible with the type series module segments will allow you to create a BiKOSequence technological line – suitable for most customers. Ready-made modules will allow you to adapt them to various needs, and also allow for quick order fulfillment. The lack of need to design machines/devices from scratch also contributes to a shorter waiting period for the product to be made and a reduction in the product cost.

Since all modules are created based on the latest industrial design – in the full design process, including cyclical prototyping/testing, they are therefore appropriately adapted to the needs of end users of devices constituting the BiKOSequence technological chain. Detailed implementation documentation is developed for each device, so we obtain a repeated product of repeatable quality, repeatable parts and solutions.

Accurate production documentation streamlines the process of ordering parts and the module production process itself by trained staff who already know such a module well as a repeatable product.

Simplified logistics – loading/unloading and transport for repeatable products, we use standard means and procedures, which will make the processes run faster.

Assembly at the customer’s is quick and efficient, thanks to the appropriate design, the module is easy to assemble and compatible with other modules ordered by the customer – and the solution has been tested many times.

Developed repair procedures and ready-made sets of spare parts – all this to facilitate repair. Modules of a given type are based on the same parts as far as possible, which streamlines the process and course of their repairs.