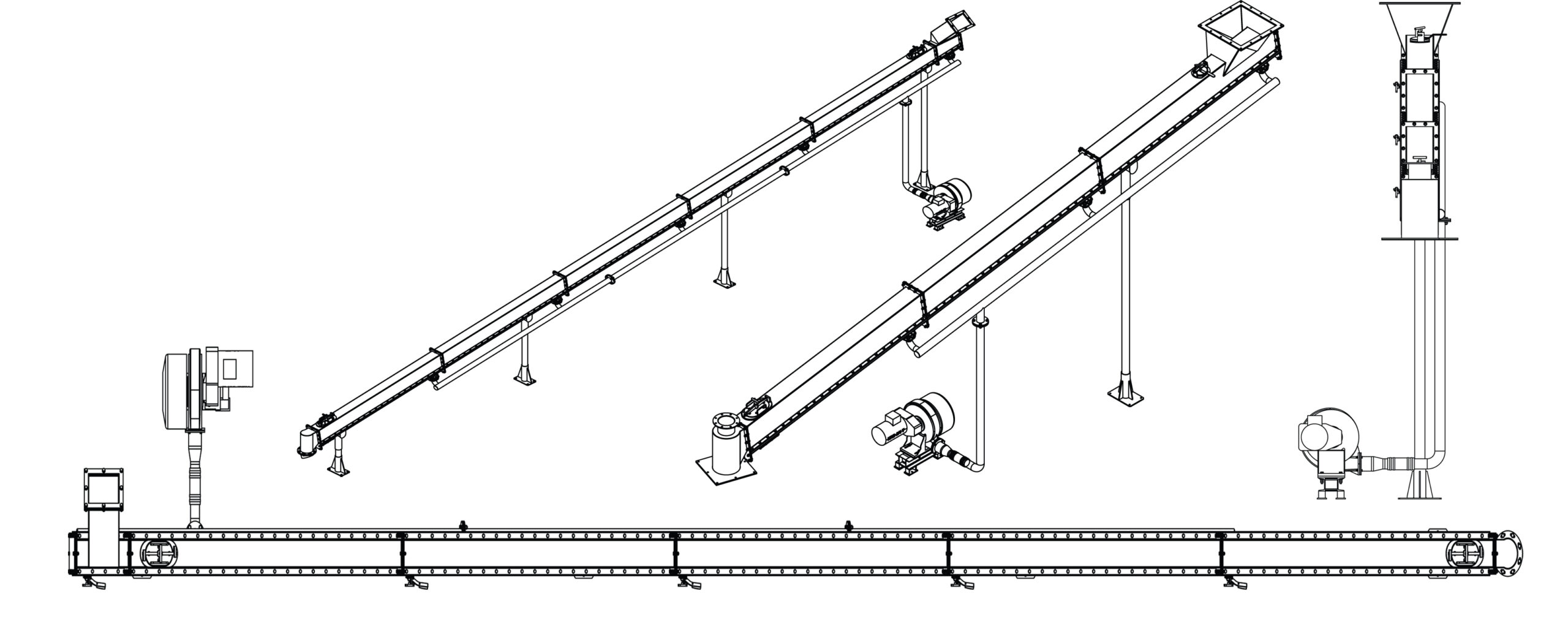

Air slides / aeration (fluid) gutters are used to transport fine and dry materials (subject to fluidization), such as: lime, raw material and lime-marl flour, cement, sand, gypsum and all types of dust.

This type of transport is characterized by very high efficiency in relation to the dimensions of the feeding device and the possibility of feeding an adjustable material stream, often in its recirculation system. Some models of aeration gutters are equipped with a channel branching, which allows the material to be divided into independent strings.

The gutter works at an angle of inclination of 4° – 15° to the horizontal, and this angle depends on the type of material. The efficiency of the device depends on the transported material, the angle of inclination of the gutter and the type of aeration fabric used.

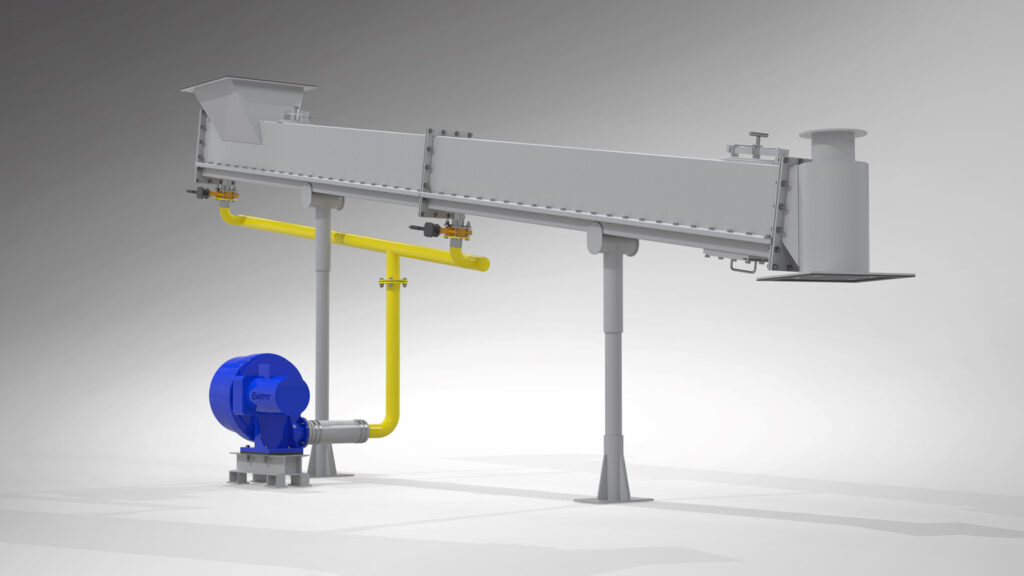

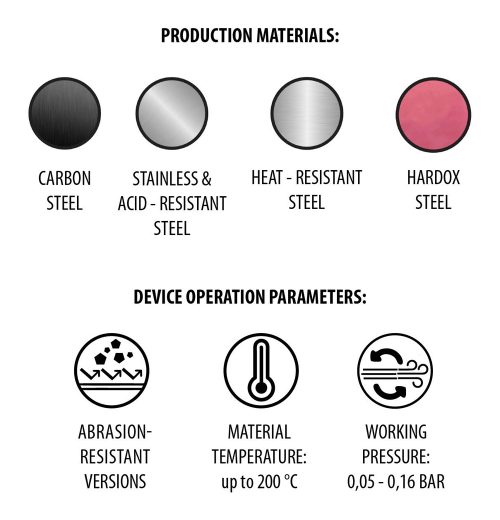

Air slides are continuous transport conveyors used to transport dry dusty and fine-grained raw materials and powdered materials, such as:lime-marl flour, cement, sand, gypsum, ashes, etc. The devices are characterized by high transport efficiency in relation to the dimensions of the devices themselves. and the ability to transport materials at higher temperatures (even in the range from 150 to 200 °C)

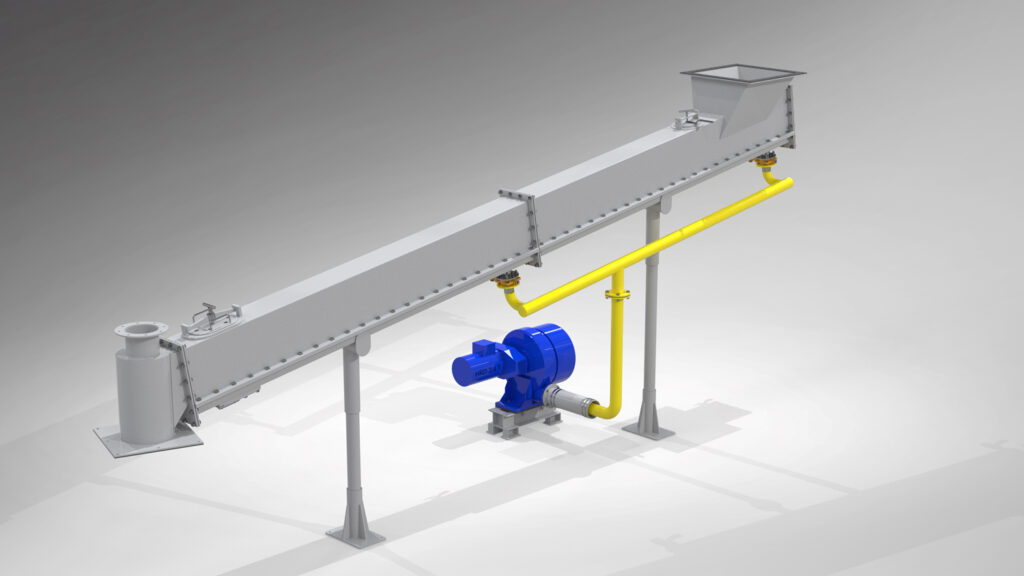

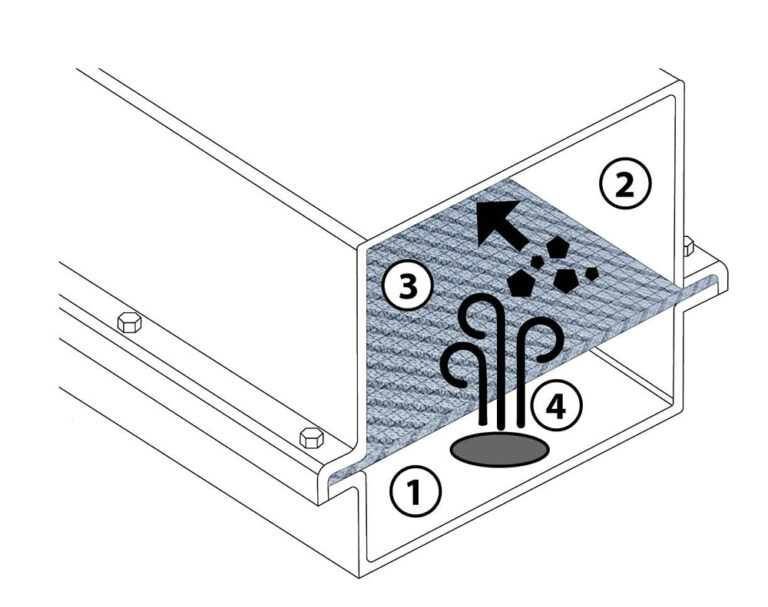

The devices consist of a tightly closed lower trough (1) and an upper trough (2). A steel grid is placed between the troughs, with a layer of special aramid or polyester aeration fabric (3) of various thicknesses (so-called diaphragms) on it. Air is supplied to the lower trough from the fan (4).

The transported raw material is dosed into the upper trough (onto the fabric). Pneumatic gutter transfer involves introducing pressurized air into the aeration chamber. The overpressure created in this way in the lower trough causes the air to pass through the diaphragm and mix with the raw material (the so-called fluidization phenomenon). The conveyed material flows at an angle of inclination down to the outlet. The gutter operates at an inclination angle of 4°-15° in relation to the horizontal, this angle depends on the type of raw material being transferred and the type and performance parameters of the aeration fabric used. Passing through the porous partitions, the air disperses and loosens the transported material. Thanks to this, that material becomes fluid and, in accordance with the law of gravity, are sent according to the slope and course of the chute.

It is possible to change direction of the material transported through the gutter into two independent routes. Depending on the required performance, we prefabricate steel gutters according to the individual technological needs of our clients.

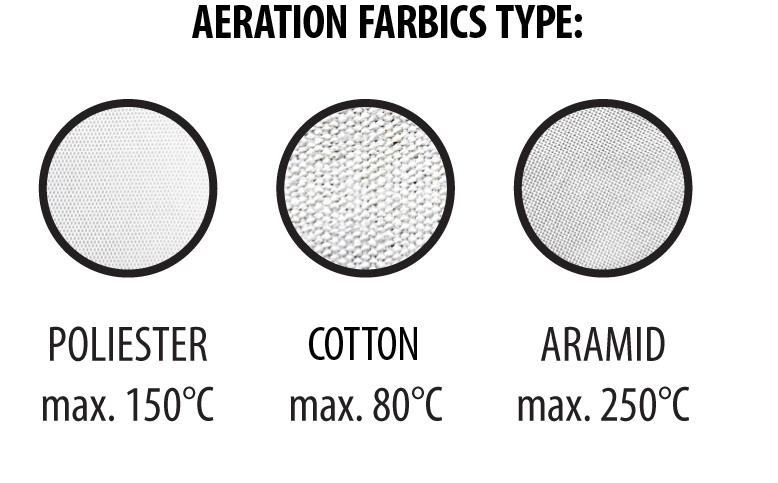

The aeration fabrics used are manufactured from high-quality polyester, cotton or aramid yarn, under constant supervision of all parameters, in particular the fabric resistance tested at a given and precisely defined flow of the transported material. Continuous control of the fabric resistance ensures, as a result, trouble-free transport of bulk materials in industrial installations. Standard aeration fabric resistances are 300 mmwg, 350 mmwg and 800 mmwg at a flow of 400 Nm³/

Fabrics with different structures, different thicknesses and different air permeability are available. They can be made of polyester or aramid. In the polyester version, the edge of the fabric is laminated, in the case of aramid canvas, the edges are protected with a high-temperature impregnation.