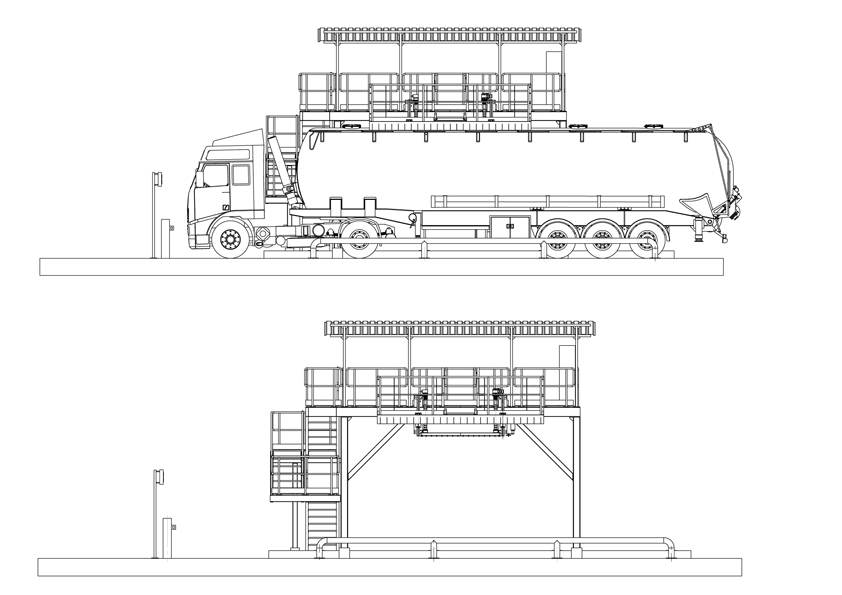

We would like to present you the only automated installation for collecting samples of materials from road tankers in Poland. The purpose of the installation is to ensure the safety of the tanker driver (it is intended to protect him against falling in all directions) and to minimize the risk of an accident while performing the so-called “other work” to virtually zero.

Safety is the basis for the operation of every factory and industrial plant. In addition to meeting legal requirements, ensuring safety is crucial to protecting workers and reducing accidents. Production and industrial plants are a source of many threats. They contain chemicals, devices and machines that pose a real threat to the health and even life of employees. It is the responsibility of both employers and employees to ensure an appropriate level of safety for employees or subcontractors. The purpose of safety policy in manufacturing companies is to ensure that all people are able to perform their duties safely. Mechanical equipment and the physical environment are taken into account here. A safe environment does not arise by chance – it must be created at all organizational levels.

It might seem that the duties of a professional driver do not include the aspect of working at height, because his task is to drive a set of vehicles with a specific total weight. However, in accordance with applicable legal regulations, work at height is work performed on a surface at least 1.0 m above ground level. Bearing in mind that drivers of vehicles above 3.5 t enter the trailer, such work is considered work at height. Road tanker drivers should be authorized to work at a height above 3 meters due to the need to open hatches on the tanker, check its filling level or to take samples for laboratory tests.

Working at heights is considered particularly dangerous work and requires the use of appropriate organizational procedures and full protection of the employee against falls from heights. The requirements of industrial plants include appropriate marking and protection of employees. Professional drivers are prepared to take care of their own safety during training and acquiring their licenses, but the obligation to ensure safety also rests with employers and companies where professional drivers perform their work.

Good conditions and properly prepared workplaces must go hand in hand with meeting health and safety requirements at a given industrial plant. Protecting the health and life of employees should be a key task for every employer. A consistent policy and compliance with the rules is the best way to prevent accidents while performing professional duties and occupational diseases.

It should be remembered that collective protection measures cannot be used in every situation. The employee should then absolutely be provided with personal protective equipment. Their use should be appropriate to the existing risk and not increase it.

Falls due to trips and slips are one of the three leading causes of injuries in manufacturing environments. The protective barrier is only on one side of the tanker and is not sufficient protection against falling from a height. Especially since the surface of the tank may be icy or dirty, e.g. with some greasy substance. The barrier also does not protect the driver against falling in all directions. The barrier has a more practical use when it comes to attaching a safety rope to it, which is part of the harness. Modern cars have a rope attached to the barrier, the employee only needs to attach it to his safety harness. However, using a safety harness is not a convenient solution.

So why build special automated installations for opening and closing hatches and taking samples from road tankers in a safe manner? It is a matter of professionalism, responsibility of our clients and the willingness to provide their employees and subcontractors with comprehensive protection.

The lowered platform for collecting samples of material from road tankers is used to collect samples of loads used in road transport; both loose, semi-liquid and liquid products. First of all, the use of a railing and a platform with a basket when taking samples from a road tanker protects the driver against falling in all directions. If the structure is equipped with other permanent elements or devices that protect the employee against falling from a height, then such activities are not classified as work at height (regardless of the height of the surface at which the driver performs activities). In practice, this means that an accident that occurred while taking samples using this type of installation cannot be classified as an accident at a production plant.

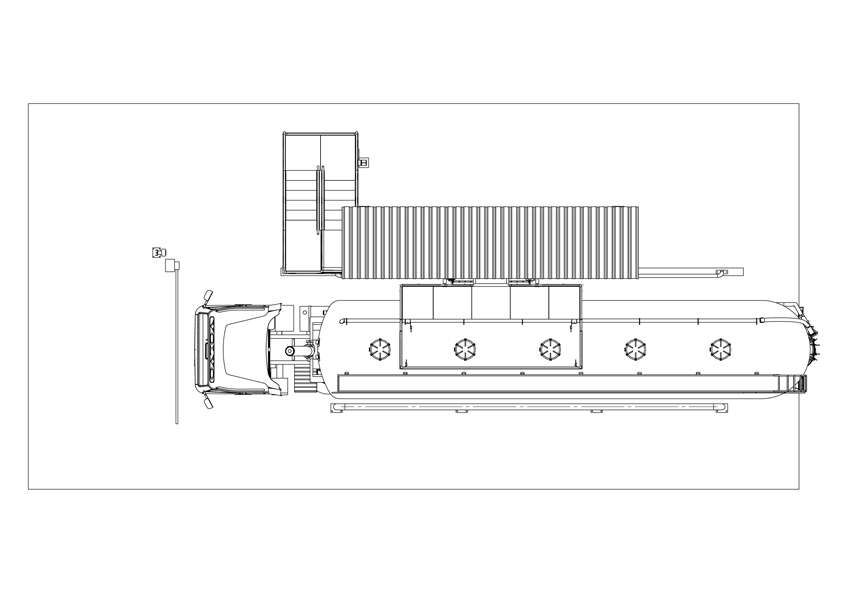

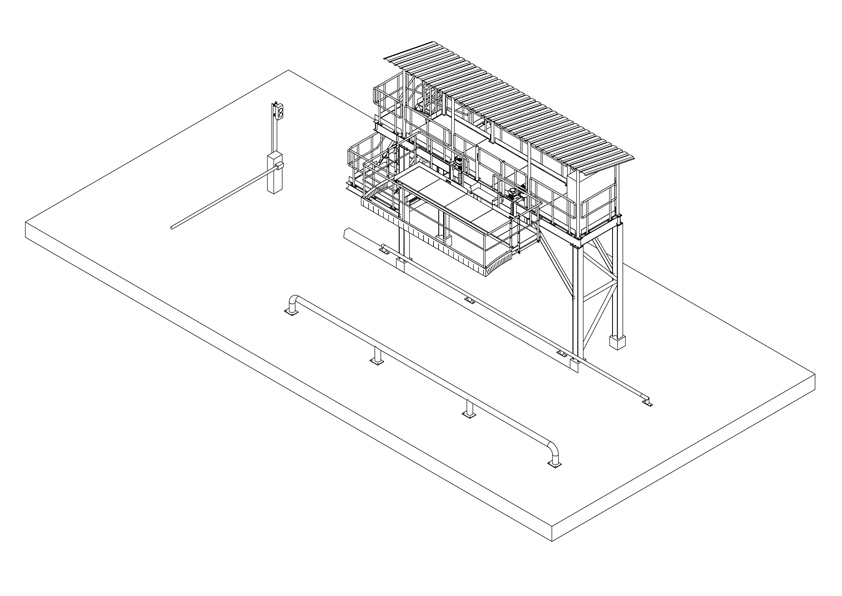

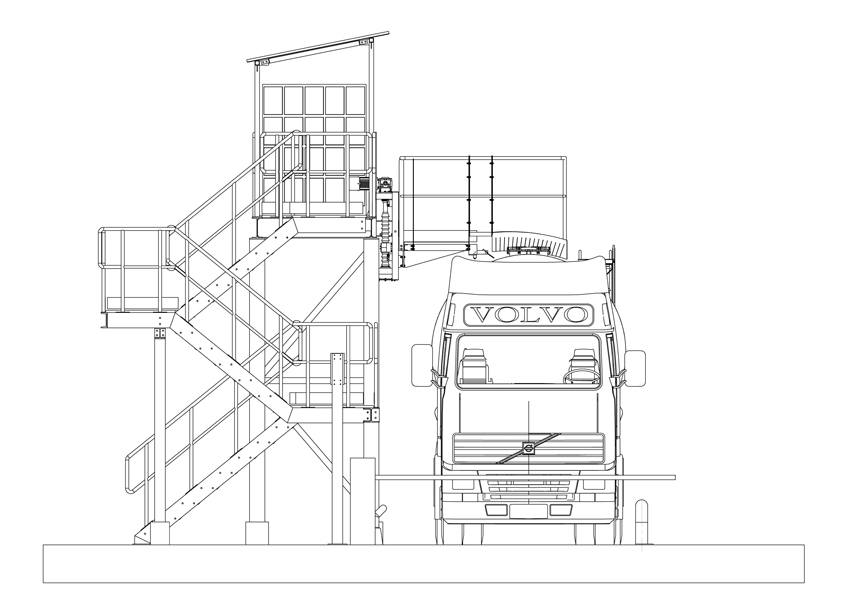

The tanker driver stops in front of a traffic light/semaphore. In order to make it easier to park the vehicle, two metal bumpers have been installed at the stand, guiding and facilitating parking of the vehicle in the right place. When the tanker truck is placed on the stand, the semaphore lights up red and the barrier is lowered. After this, you can proceed to activities that allow you to safely open the hatch and collect the transported material:

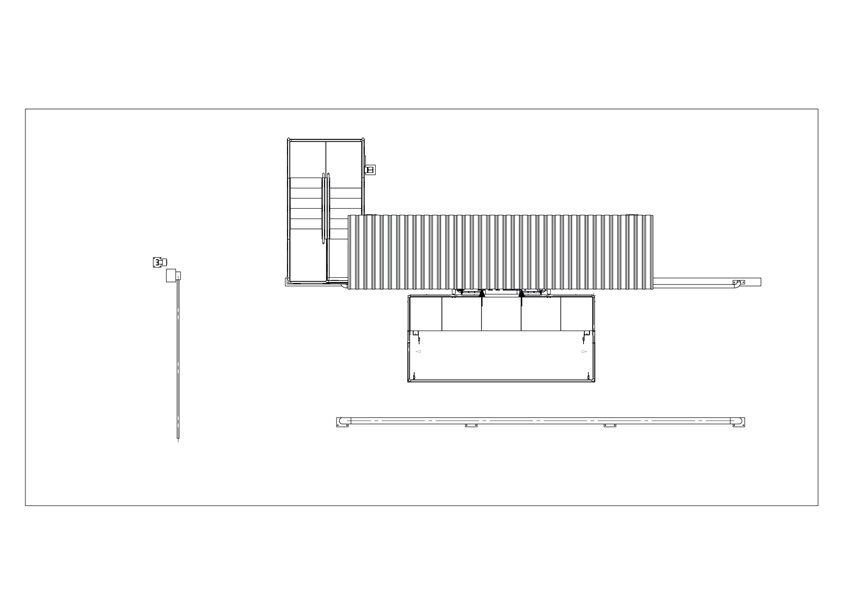

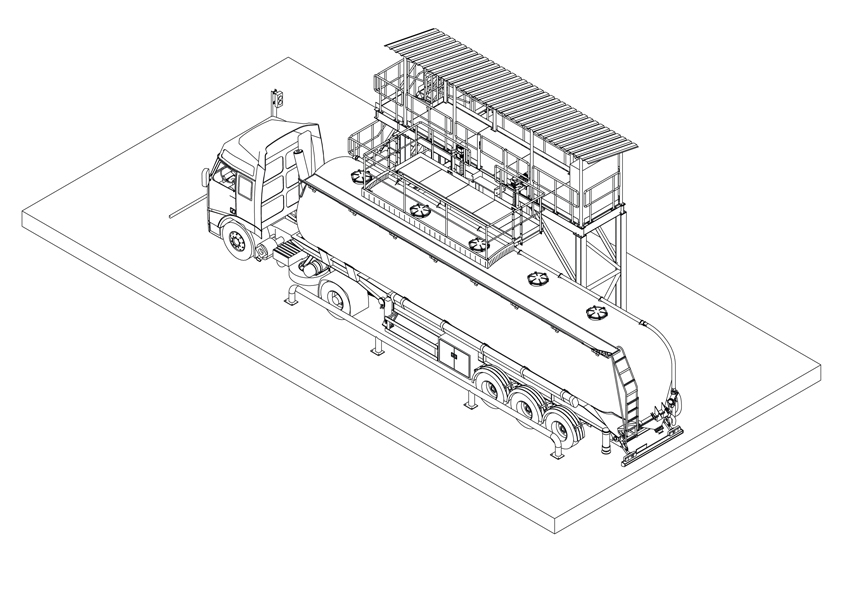

The installation designed by Biko Tech is roofed and illuminated, the construction area and the usable area of the installation is 18 m2. Prior preparation of the foundation at the installation site is required.

Because the platform is entirely metal, grounding, lightning protection and fire protection are installed. Steel structures and welds were protected against corrosion by painting with an epoxy primer and specialized anti-corrosion paint coatings in class C3-C5 (depending on the customer’s requirements). Resistance to changing weather conditions is crucial for installations operating outdoors. The operating temperatures of the installation are very high and range from -20 °C to +40 °C.

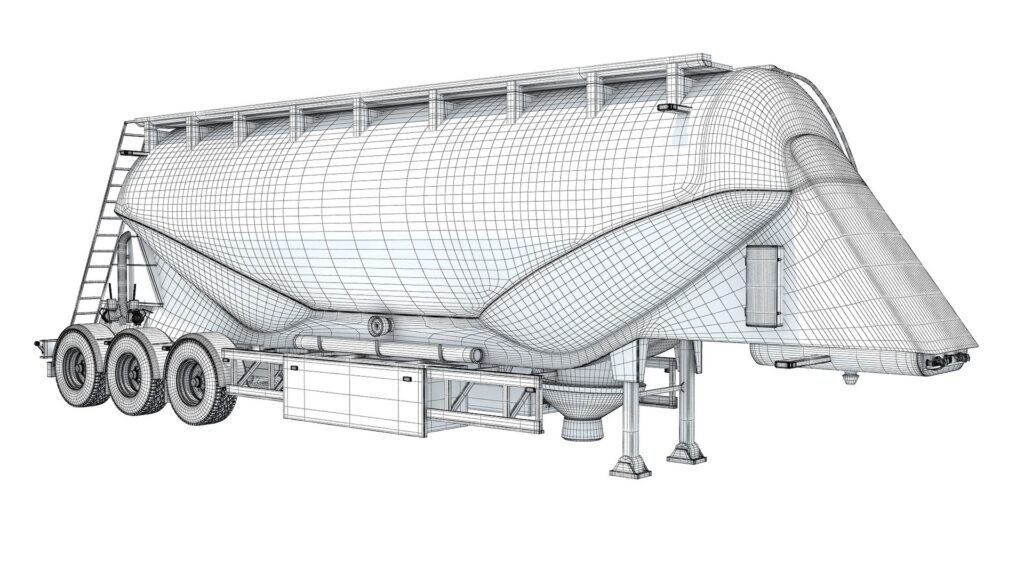

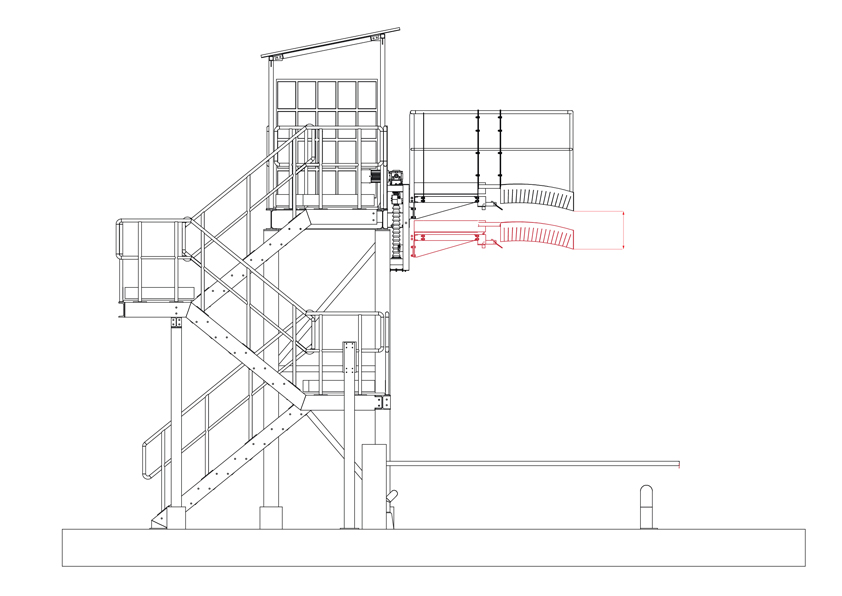

The platform consists of a fixed part and a movable part, which allows you to safely open the tanker hatch and take a sample of the material inside. The operating range of the movable platform is ~ 3700 – 4300 mm. The driving element is an electric screw lift (electric motor power 1.5kW, motor voltage 230/400VAC (50Hz), output torque 128Nm) and a worm gear motor. The platform is lowered using a two-column screw gear in an up-down arrangement. The permissible load of the ready-to-operate mobile platform is ~580 kg,

The installation uses high-efficiency and ecological components, such as electric drive sources. The installed electric motor has the energy consumption class IE3 – Premium Efficiency (according to the IEC 60034-30:2008 standard).

The installation does not use pneumatic systems. Firstly, it eliminated the need to make connections to installations of media other than electricity. Secondly, due to the fact that the installation operates outdoors, in the autumn and winter period there could be problems with the operation of the installation and its increased failure rate.

Thirdly, the air supplying pneumatic systems in industrial installations requires appropriate preparation, i.e. installing an air preparation unit of the appropriate class and appropriate operating parameters. Air preparation includes: filtration of solid impurities, drying and de-oiling it, and appropriate pressure regulation. The components listed above plus valves would significantly increase the cost of the installation itself.

The lower extreme position of the platform is carried out using inductive limit sensors that detect the road tanker. The upper and lower position of the platform is detected using proximity sensors. The intermediate position (including detection of the presence of a road tanker) is performed using four mechanical limit sensors.

Access to the movable platform is secured by a gate, which can be opened only when the movable platform detects the presence of a road tanker, in other words, when the road tanker is not parked at the stand, the gate remains permanently closed and it is not possible to enter the moving part of the platform. In light of the above, the risk of the operator falling from the mobile platform has also been significantly minimized. The installation operator is informed about the closing or opening of the gate by a light signal at the control desk.

The installation controller can be any, adapted to the standards adopted by our clients. Regardless of what control system is selected, operating the system itself on the part of the tanker driver involves pressing two buttons on the control panel (marked “Up” and “Down”). Lighting (5 light points) automatically controlled by a twilight sensor is installed on the fixed platform, which also significantly improves the safety of use of the installation and automates its operation.

One of our main goals when designing the sampling installation, apart from ensuring safety of use, was to simplify the operation of the installation as much as possible and make it easier for operators/drivers to use. The installation operation has been simplified and reduced to an absolute minimum.

The installation for taking samples from road tankers manufactured by Biko Tech is certified and CE marked, which proves the product’s compliance with EU regulations relating to the product and certifies that the product meets the requirements of Directive 2006/42/EC (MD) – Machinery.

When the CE mark appears on a product, we are sure that it is as safe as possible, does not adversely affect the natural environment, and in the production process, care was taken to reduce the consumption of electricity, water, noise emissions and other important parameters.

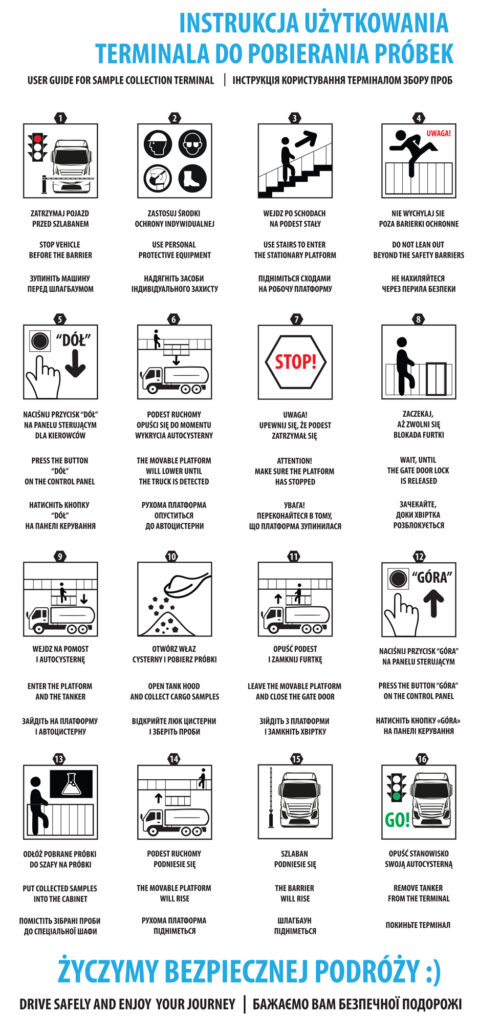

The Biko Tech installation is delivered with technical, operational and service documentation. Simplified instructions for use, in the form of boards with pictograms, are also delivered with the device. One board is installed near the semaphore and the barrier, i.e. at the place where the driver leaves the tanker cabin and has the “first contact” with the installation, the second board is located directly next to the control panel, near the installation’s movable platform.

The boards are arranged in accordance with the rules regarding their proper visibility and readability – otherwise they could go unnoticed by employees, which could consequently endanger their health and life. As a manufacturer, we have made sure that in the workplace of the installation operator, there are instructions and safety signs that give employees tips, help protect them from danger and indicate what they should do and what they cannot do and how they should evacuate themselves in a threat situation.

Pictograms ensure proper visibility and readability of the simplified instructions. Instructions for the using of the installation are presented with subtitles in Polish, English and Ukrainian. The instructions are aimed at eliminating dangerous behaviors and activities that play a key role in improving the level of safety at the industrial plant.

The installation documentation and operating instructions were developed in cooperation with occupational health and safety inspectors who perform advisory and monitoring functions on behalf of our client. The aim of the consultation was to eliminate as many threats as possible and correctly label the installation. An important task of the inspectors was to analyze the safety of use of the installation and the existing threats.