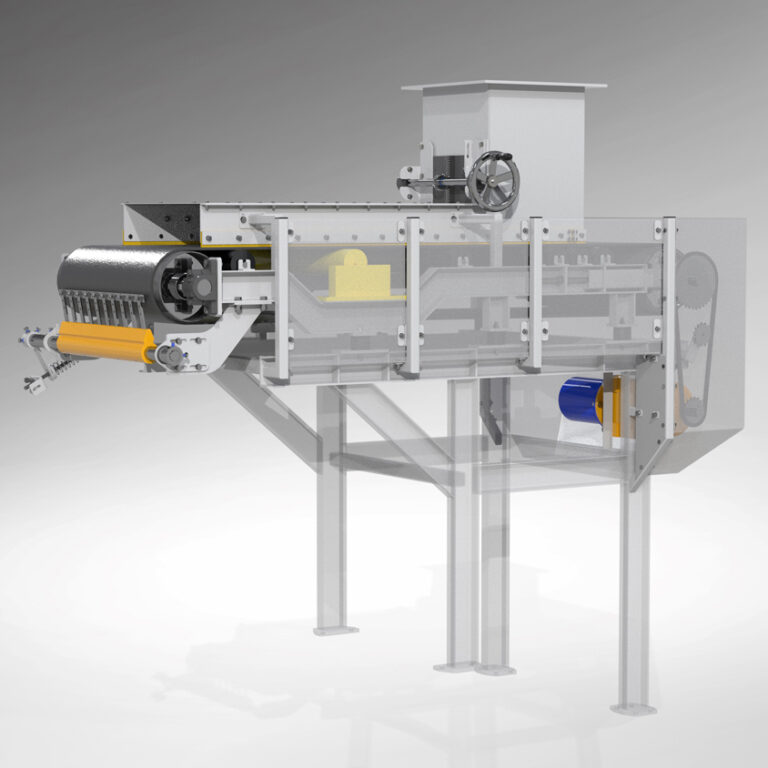

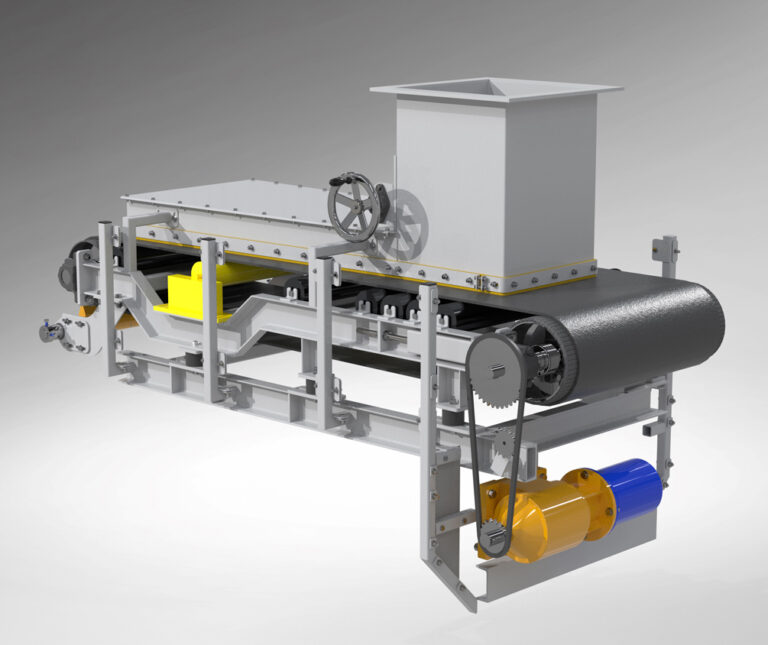

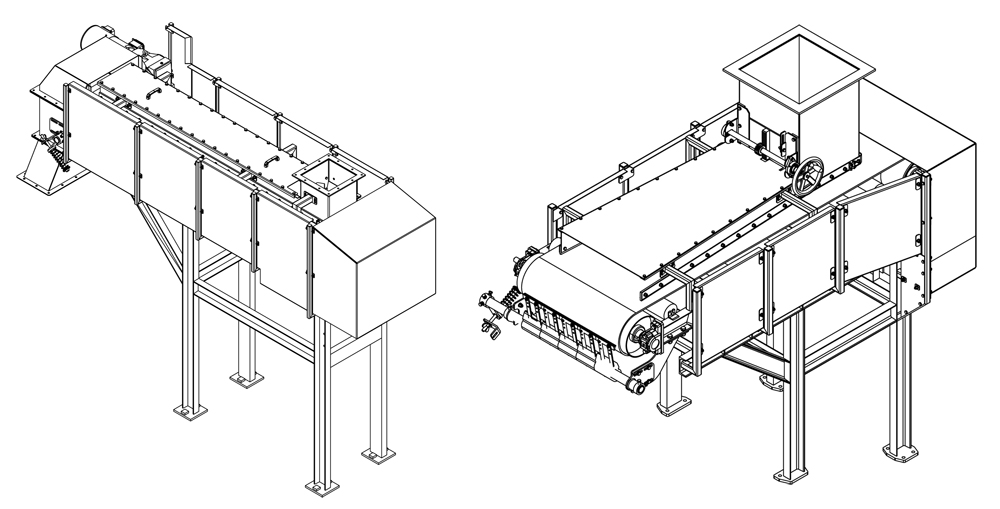

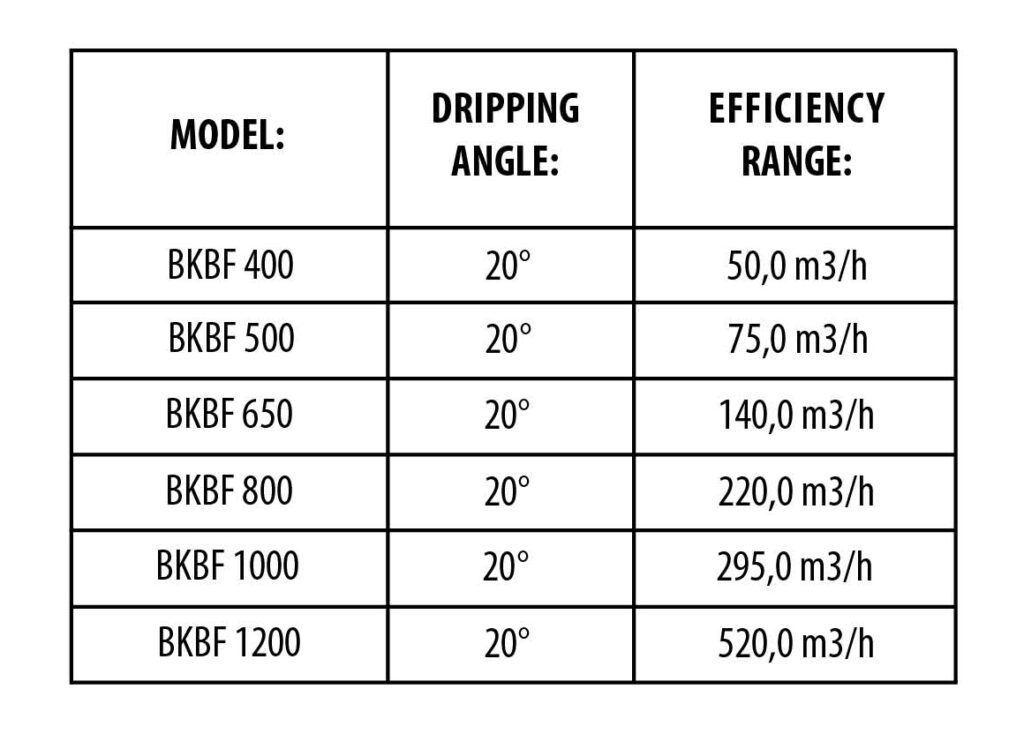

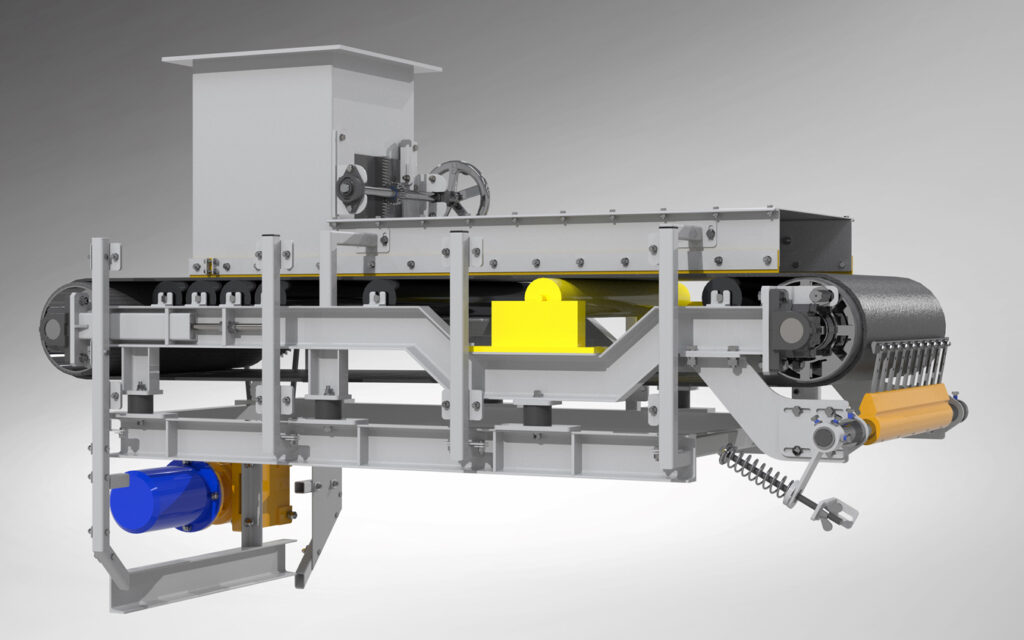

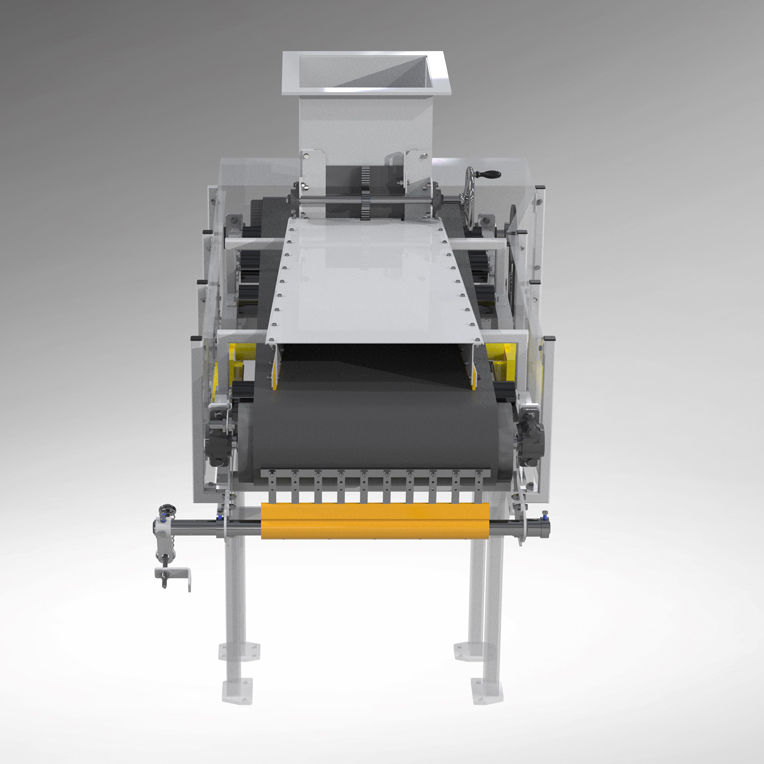

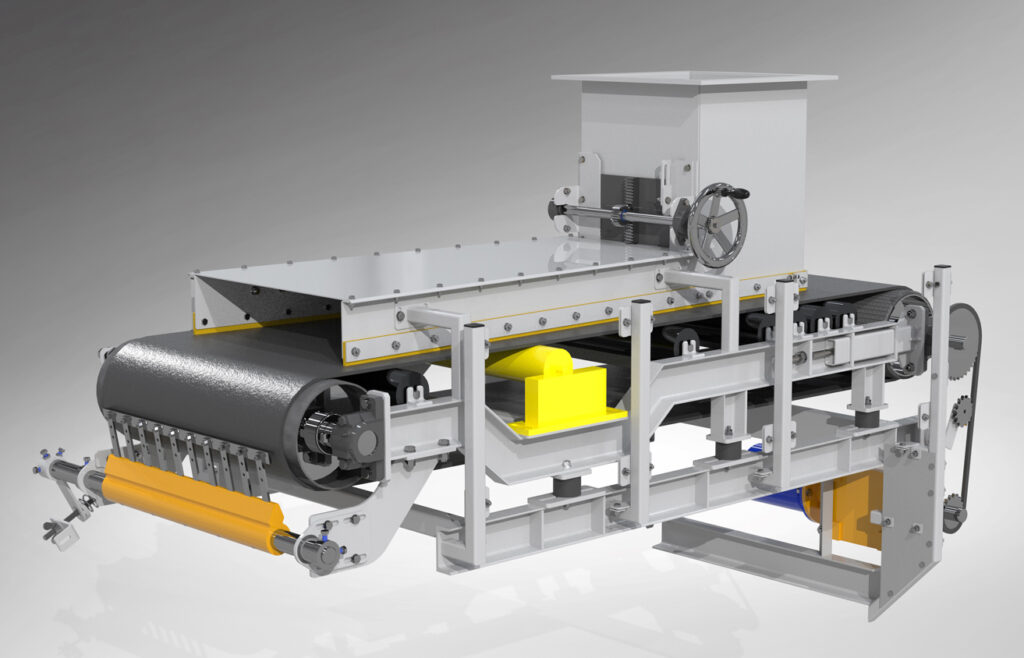

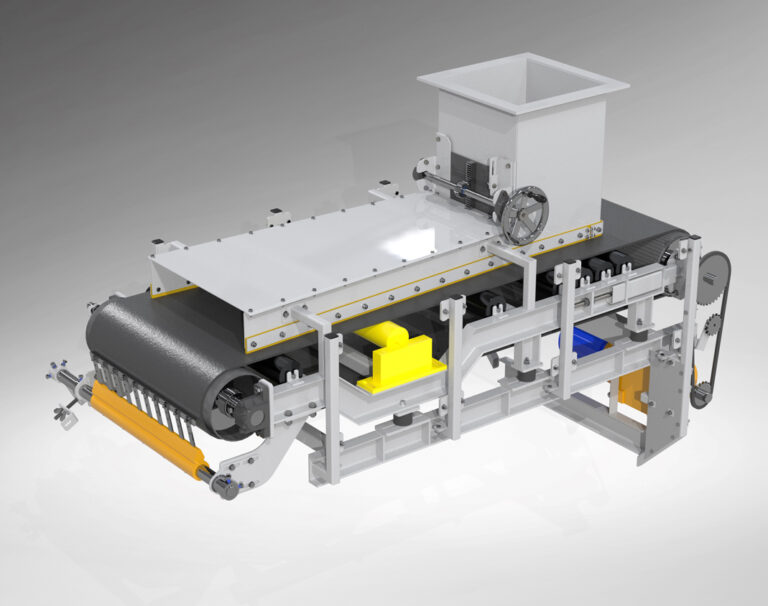

BKBF belt feeders by Biko Tech are a type of conveyor whose construction was designed primarily for measuring the flow of bulk and small-piece materials. Versions made of black steel are used in heavy industry, e.g. in the cement & lime industry and in the production of building chemicals.

Belt feeders are used for smooth and even feeding of bulk and lump materials with medium and high bulk density. They enable dosing during transport, especially for products that are difficult to to come off. These devices are used primarily for transporting materials at subsequent stages of production, selecting raw materials, transferring aggregates, and both: their packaging and loading into transport vehicles.

These devices are certainly the most universal solutions for feeding bulk materials, those manufactured by Biko Tech have been designed to work in the most difficult conditions. Stations with a belt feeder are commonly used, among others, in production plants, mines and warehouses.

Depending on the type of scale, these devices can also have portioning and dosing functions using gravimetric methods. Material feeding and dosing can be continuous or batch. They can also be used solely to sum up the flowing material. Raw materials can be dosed in two ways. The first method is by feeding a constant layer of material at an adjustable speed, the second method is by regulating the material feed onto the weighing conveyor, through layers that determine the size of the material on the belt or through pre-feeders. BKDF feeders can be made in an open or closed version – in a dust-proof housing. This means that belt feeders not only have a built-in belt scale, but all their elements are made with high precision.

Thanks to the precision of their workmanship, belt feeders are particularly useful for feeding delicate products: powders, granulates, pellets, etc. Perfect for fragile products that may be damaged during dosing. They are perfect for the food, chemical, cosmetics and pet food industries.

Typical belt conveyors equipped with flow scales are often too large or not designed to achieve high accuracy over a long period of use and in changing environmental conditions. Bearing in mind that dosing accuracy is usually associated with lower material losses or higher quality of the final mixture, we have created BKDF conveyors.

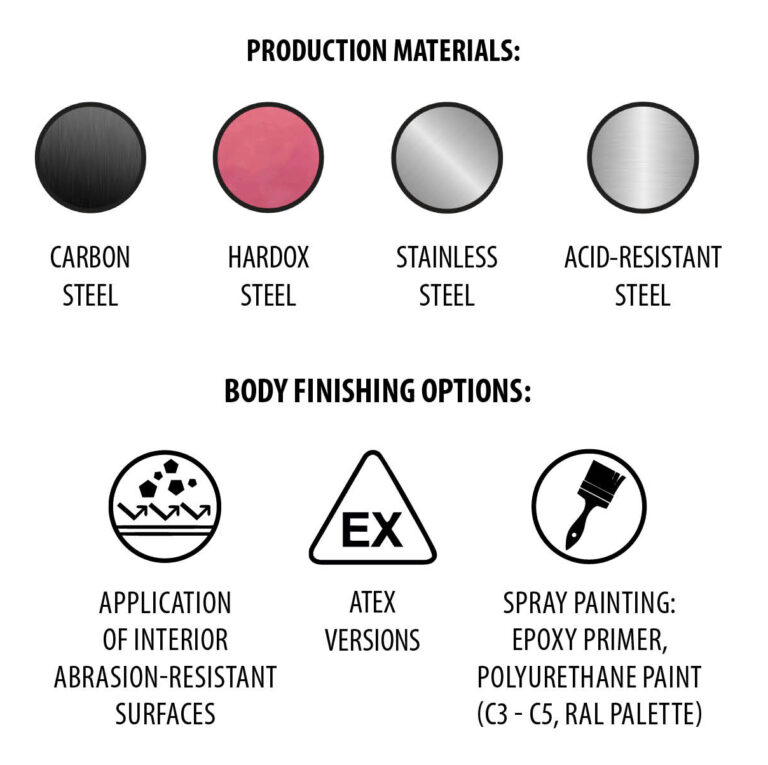

Stainless steel versions are most often used in light industry – in the food, chemical, cosmetics and similar industries. Different variants of hoppers allow for correct operation with materials that are theoretically difficult to dose – highly abrasive, easily aerated, with a tendency to uncontrolled flow or clumping.

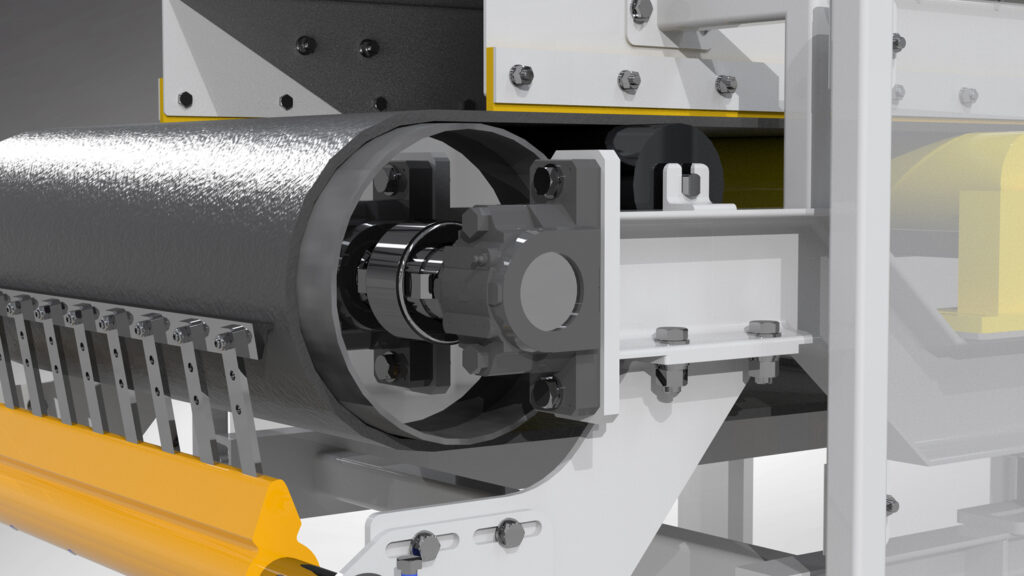

High quality workmanship and durable materials allow for long-term and failure-free operation, while ensuring high dosing accuracy. The dosing station is usually based on a solid, steel support structure. We take care of the proper selection of belts, gravity tension and belt guiding system. The high accuracy (maximum error below 0.5% of the set value) achieved over a long period of time is worth noting. It places our Biko Tech belt dispensers at the forefront of this type of solutions available on the market. The dispensers are always designed and manufactured according to the requirements of our Customers.