We specialize in a low-pressure, dispersed phase pneumatic transport, designed for capacities of 0.1 – 20 tons/hour and transport distances of up to 150 meters.

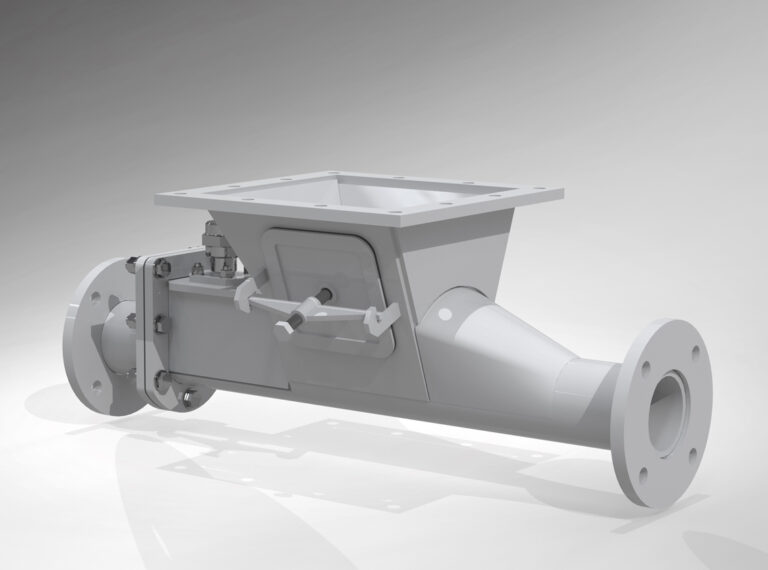

The basic element of pneumatic transport is the injector, which is used to transfer/transport loose materials and gases, its operation is to create a pressure difference between the pressure in the suction tank and the pressure in the discharge chamber. The injector must be powered by a compressor or fan.

The advantage of injectors is the lack of moving parts, and therefore high reliability. The disadvantage is low energy efficiency, but sometimes they allow the use of waste energy, which increases the efficiency of the entire transport device.

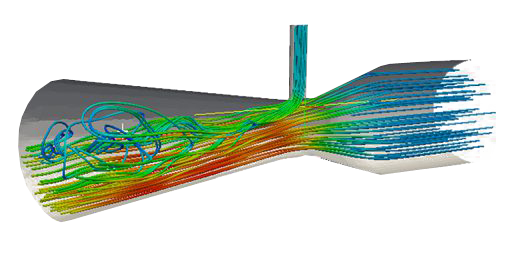

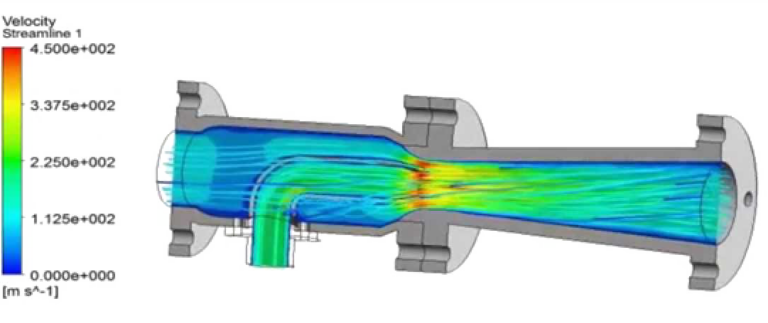

Thanks to two-stage CFD and DEM simulations, the pneumatic transport system is maximally adapted to the transported product. CFD stands for Computational Fluid Dynamics and is a type of computational fluid and gas dynamics that uses a numerical method to solve and analyze problems related to fluid and gas flows. It is a type of computer simulation that can be used to predict the behavior of air and other fluids during various interactions.

Another technique is the Discrete Element Method (DEM), which models the behavior of an object by simulating interactions between individual particles, such as collisions and frictional forces. Additionally, fluid simulations use techniques such as the Navier-Stokes equations, which simulate the behavior of fluids, as well as air and fluids. These techniques, along with others such as particle systems, inverse kinematics and rigid body dynamics, work in tandem to create realistic results.

Pneumatic transport of bulk raw materials involves putting the material particles in motion by the movement of gas molecules (usually air) in the pipeline. Air movement is created as a result of the pressure difference between the beginning of transport (sending) and the end of transport (receiving).

Low-pressure transport is powered by blowers. The material to air ratio is low and the feeding is done via injectors. Pressure and vacuum versions are used here, depending on the requirements.

The low-pressure transport set includes a special rotary feeder and an injector that shapes the material stream. Pressures for low-pressure transport are 500-1200 mbar, blower power: 5-50 kW.