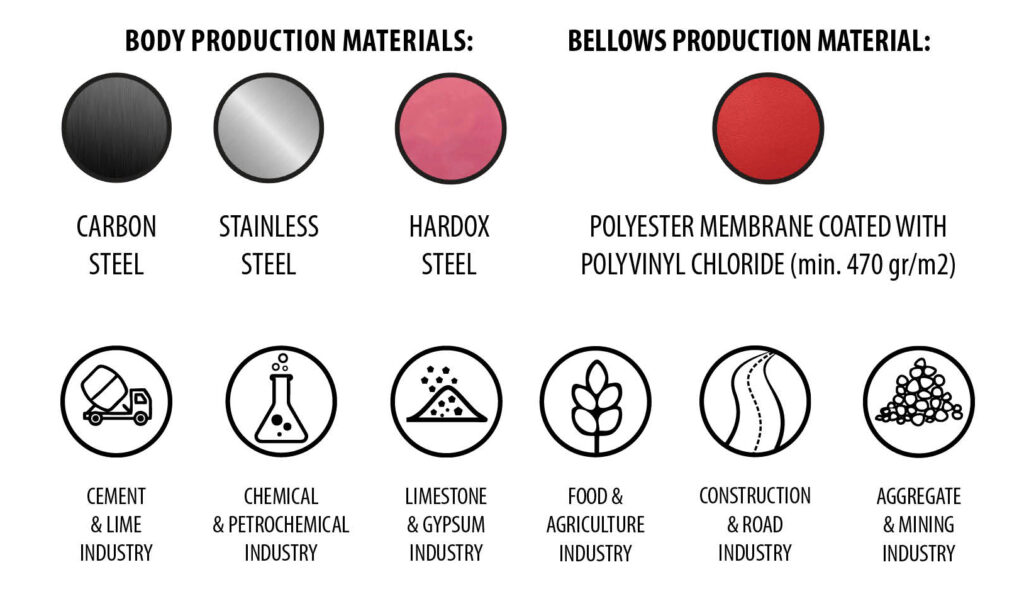

Loading sleeves are widely used in the food, chemical, pharmaceutical and construction industries. These are devices with different performance and speed of operation. We specialize in solutions enabling dust-free loading of bulk materials into barrels, tanks, semi-trailers, box trucks, ships and heaps. The latter devices include: telescopic loading sleeves with increased efficiency.

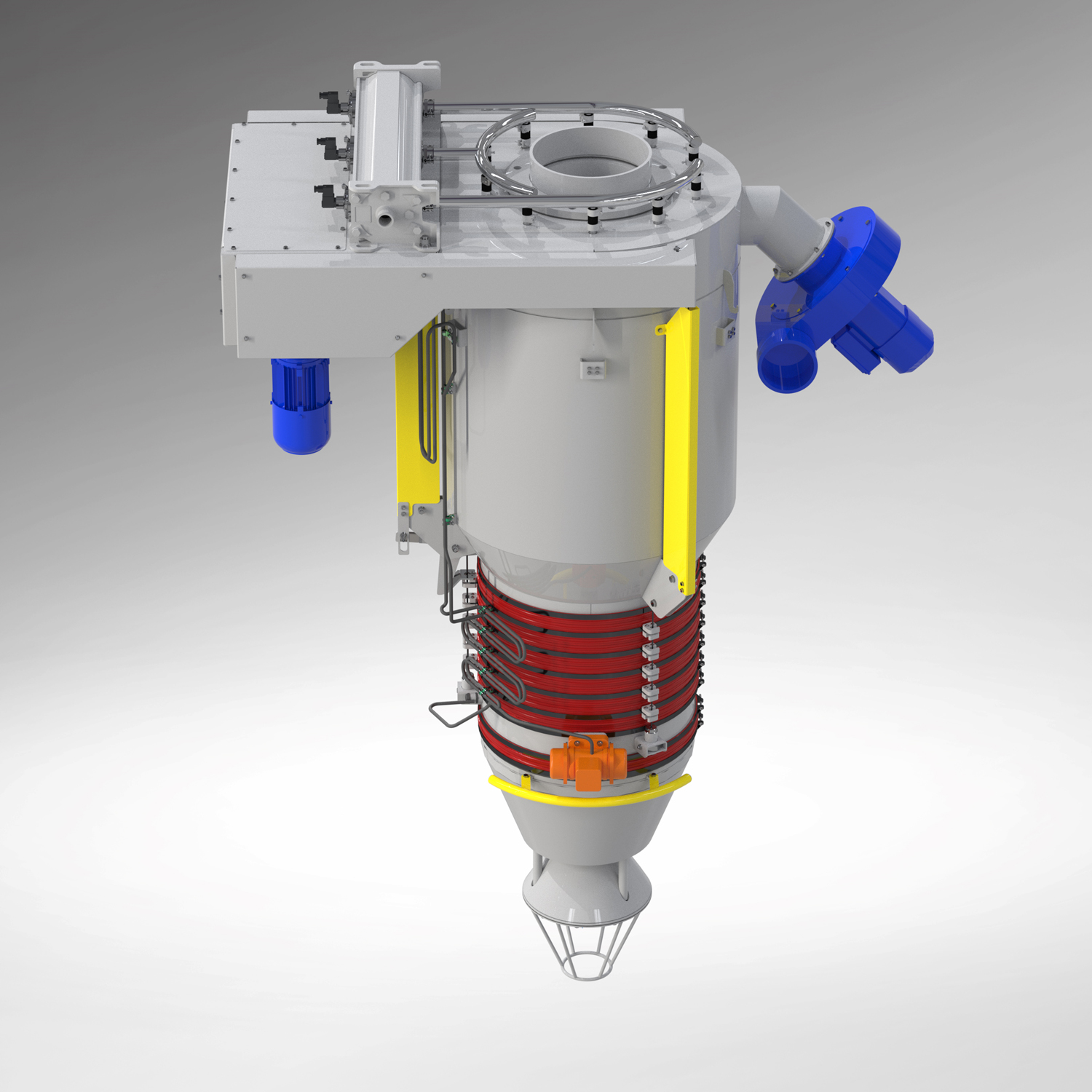

Our loading sleeves enable efficient and dust-free transfer of bulk materials for both transport and storage. It is possible to install an internal scale, positioners for three X/Y/Z axes, dust filters, an anti-dust system and support for filling the transport vehicle with the loading sleeve.

We only provide proven solutions, so you can be sure that the offered products will work in every situation and will serve you for many years.

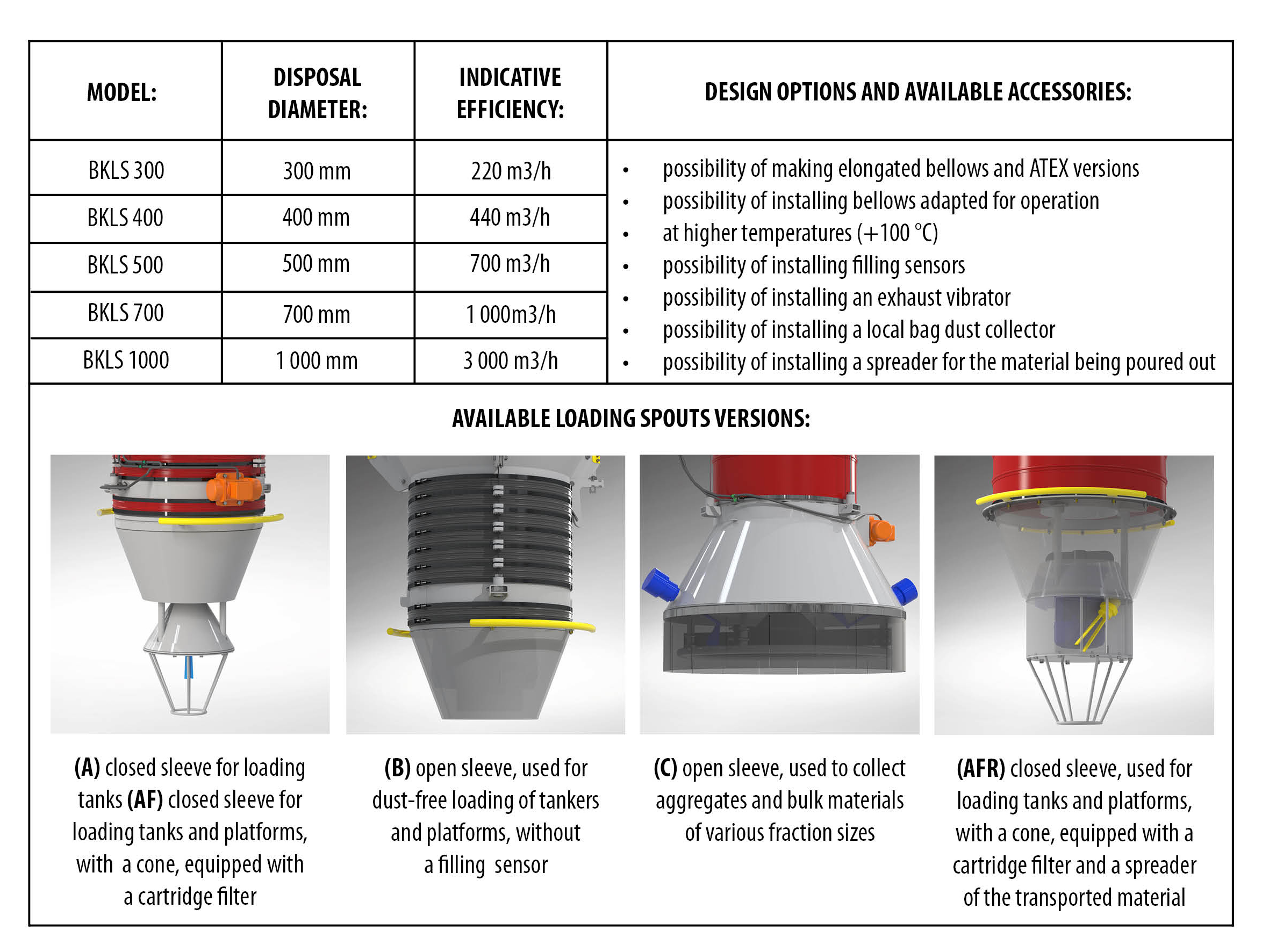

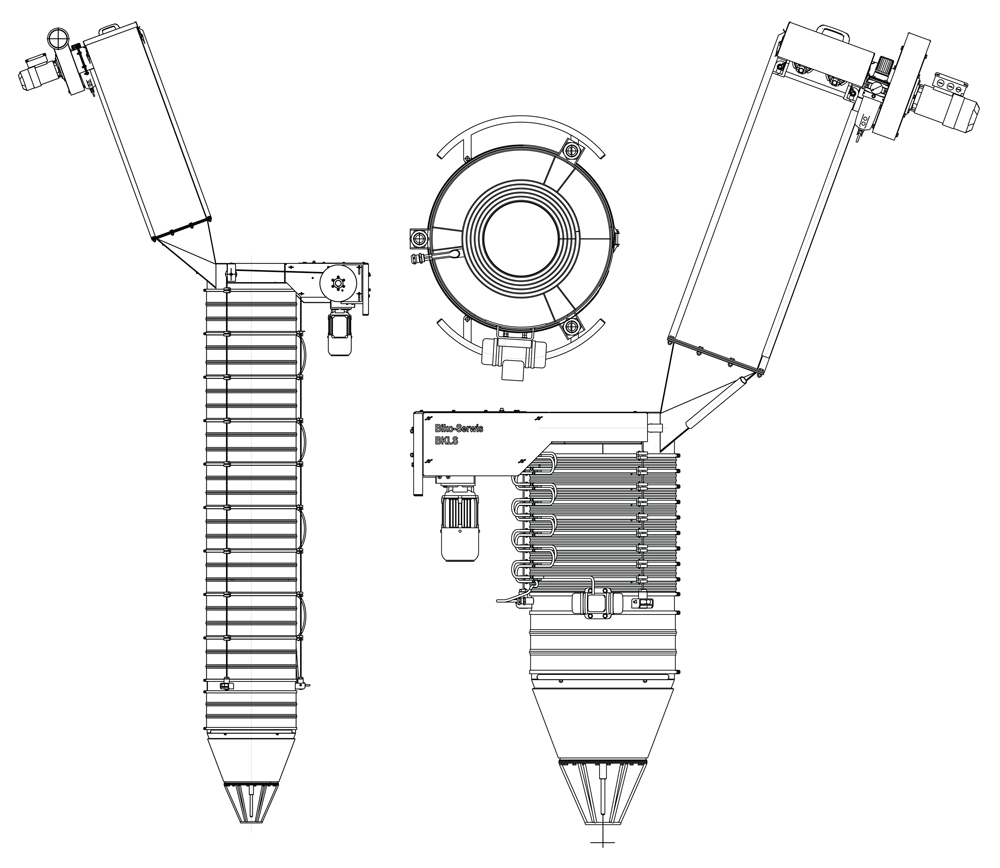

Telescopic loading sleeves are used for dust-free loading of dry bulk materials and small pieces in road and rail transport. The sleeves are made of internal cones responsible for directing the flow of material. Bellows compensators are used on the outside to ensure dust-free operation of the sleeve.

The loading bellows is lowered using an electric winch onto the tank stub pipe or the bottom of the truck. After reaching the destination, the bellows stops using the limit switch installed on one of the lines, which means that loading is ready.

Depending on the application, the lower part of the bellows is equipped with a special cap for loading tanks or an open outlet for loading platforms and trucks. Sleeves equipped with a fill sensor provide an additional signal to stop loading. Dedusting of the loading is ensured by an integrated filter or connection to an external installation.