Mixers are devices used to thoroughly mix at least two different substances, without loss or modification of their physico-chemical properties. The qualitative process of mixing products, semi-finished products and raw materials is not only about combining the above-mentioned components. A mixer properly adapted to the process speeds up production, reduces energy consumption and generates a high-quality product.

BKSM mixers manufactured by Biko Tech are used for quick and accurate mixing of several ingredients in the form of solid, loose and dusty bodies (they are especially useful for materials of different sizes and densities) in order to obtain a homogeneous mixture.

Mixers are used in virtually all industries: from agriculture, food industry, plastics processing, to the pharmaceutical, paper, construction and manufacturing industries. Wherever it is necessary to obtain homogeneous mixtures with maximum optimization of process economy and reliability.

Mechanical mixing is the most popular, least trouble-free and most economical method of mixing loose products. An industrial mixer with a properly matched mixer to the process increases the speed of producing the finished product and reduces energy consumption.

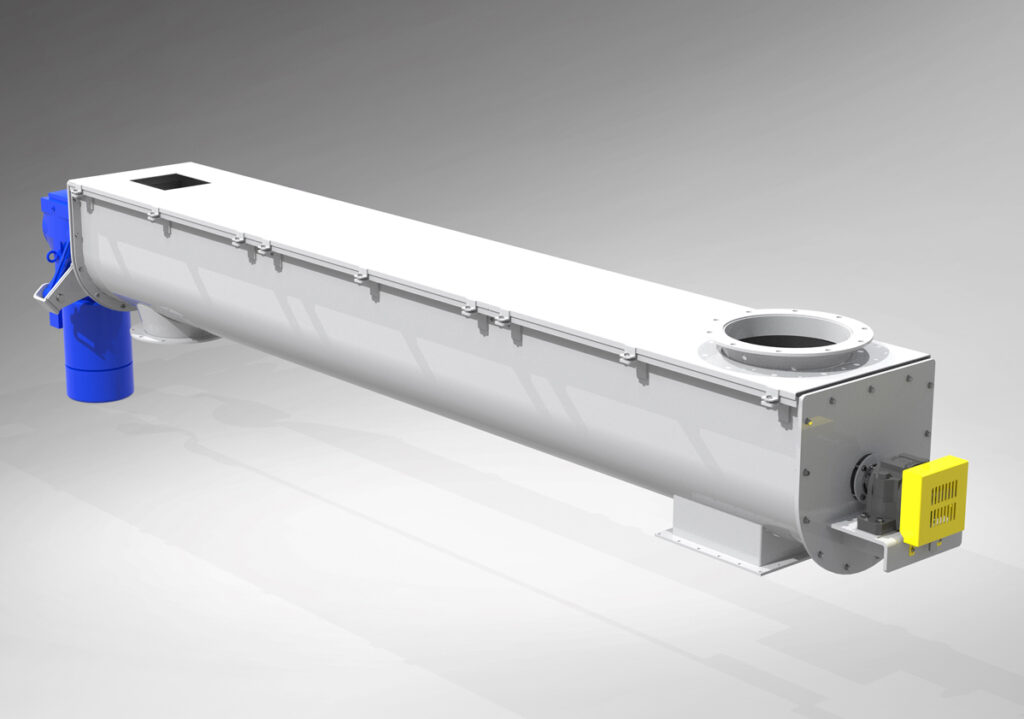

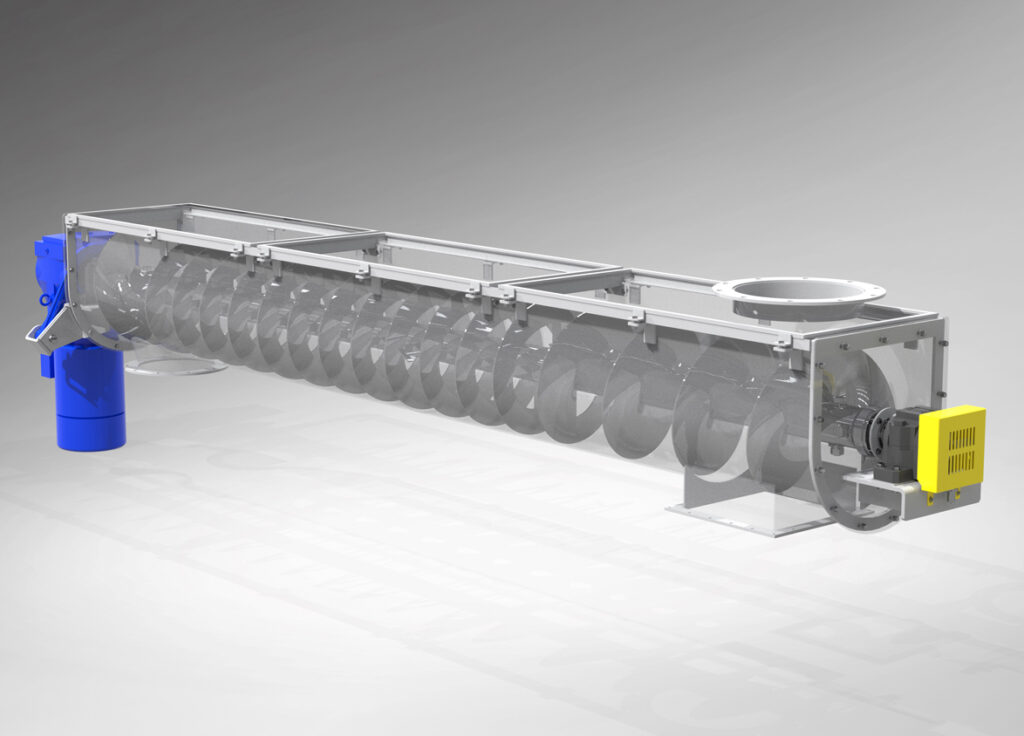

Screw mixers enable operation in both continuous and batch mode, have high efficiency and can operate in a multi-stage system with continuous mixing associated with material transport.

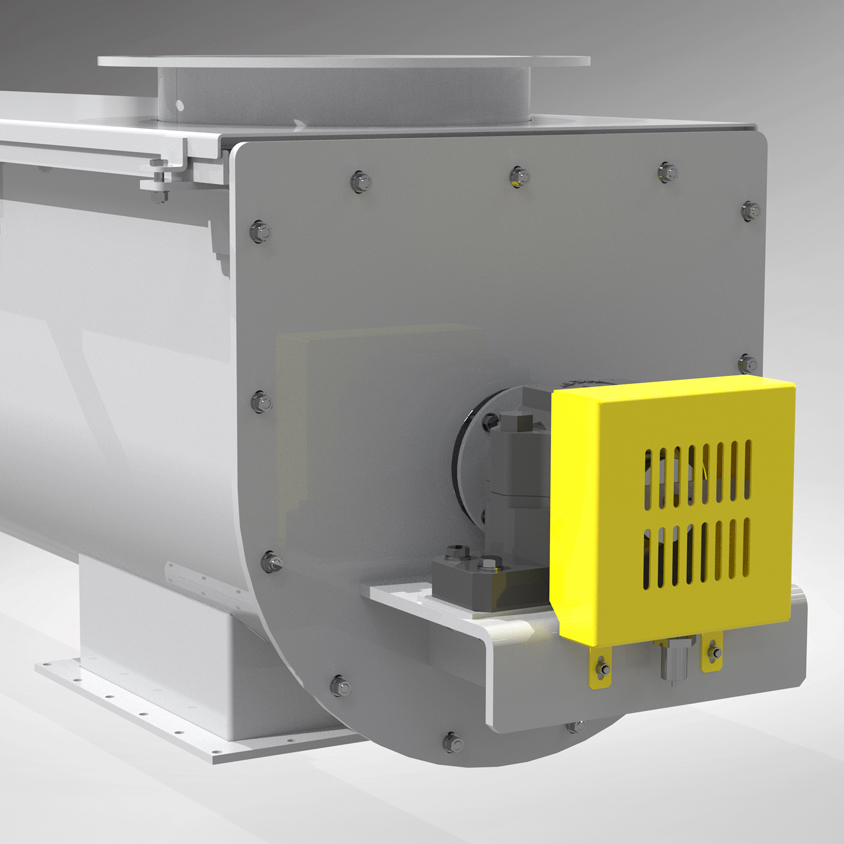

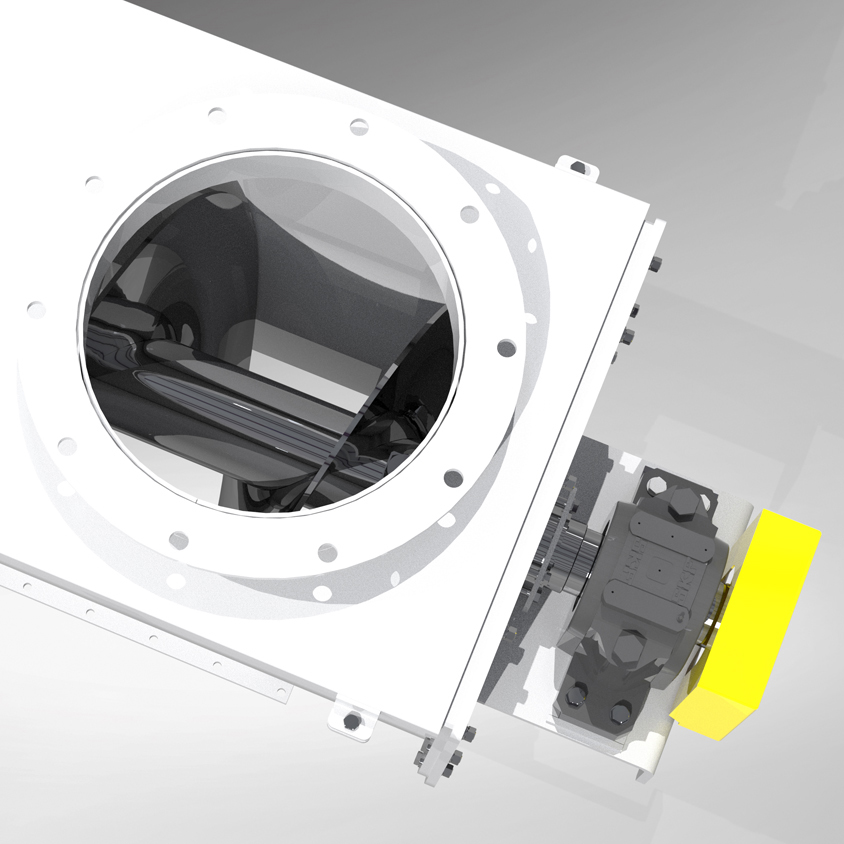

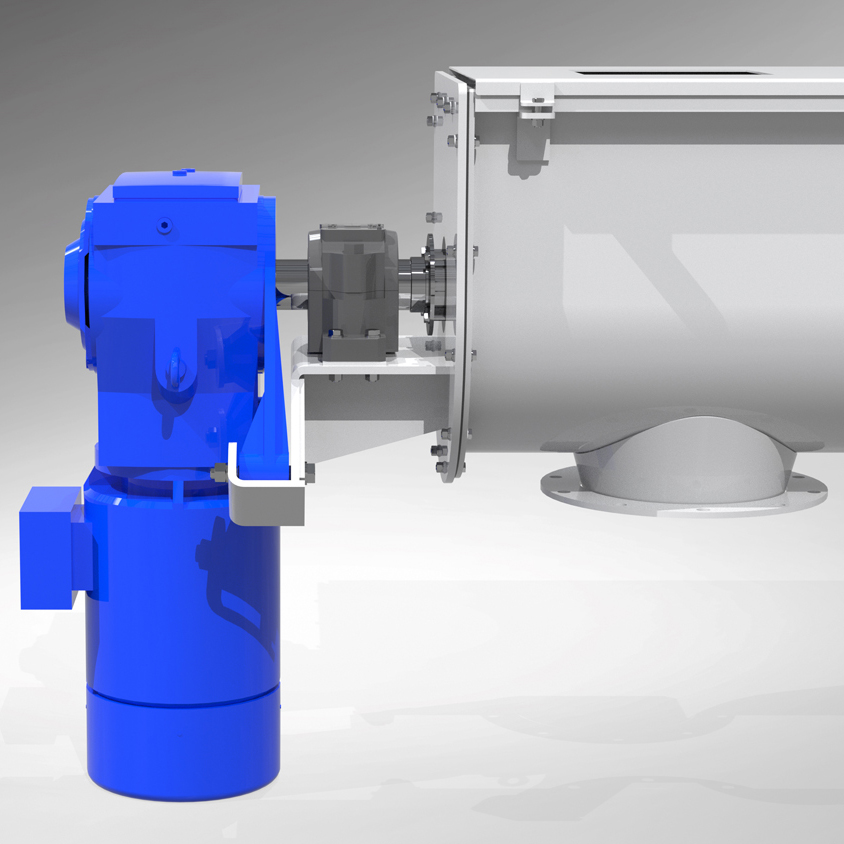

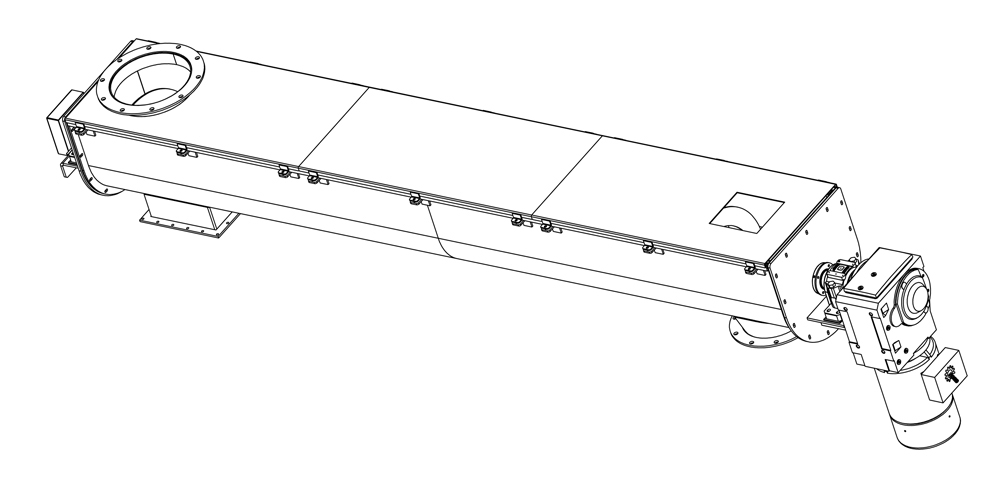

The construction of screw mixers is relatively simple. The trough (usually of tubular construction) is equipped with at least one inlet and outlet port, a welded flange at each end of the outer tube, helicoidal helical spirals welded to the central tube with a coupling sleeve at each end, two end bearings preceded by a self-aligning shaft seal, and intermediate bearings , depending on the total length of the mixer.

The device is driven by a gear motor with parameters selected according to the given application, device efficiency and the type of components mixed in it. Mixers can have single- or double-shaft designs. In the second case, it is necessary to create a system of spirals with counter-rotating directions of work.

Screw mixers usually serve the function of feeding the mixed raw material directly to the working part of other elements of the technological line or storage tanks. Feeding can take place horizontally, as well as in the case of angular mixers, at a given height.

BKSM screw mixers are designed based on simulations of the homogenization of bulk materials using the discrete element method (DEM).

Single-shaft mixers can be connected to the power grid directly or via an inverter. Controlling them is very simple and involves turning on and stopping the drive. The devices do not require a complicated control system. In the case of twin-shaft mixers, the mixing process is usually progressive and requires a control system that performs the functions of changing the direction of rotation / opening and closing valves at the inlet and outlet while filling and emptying the mixer.

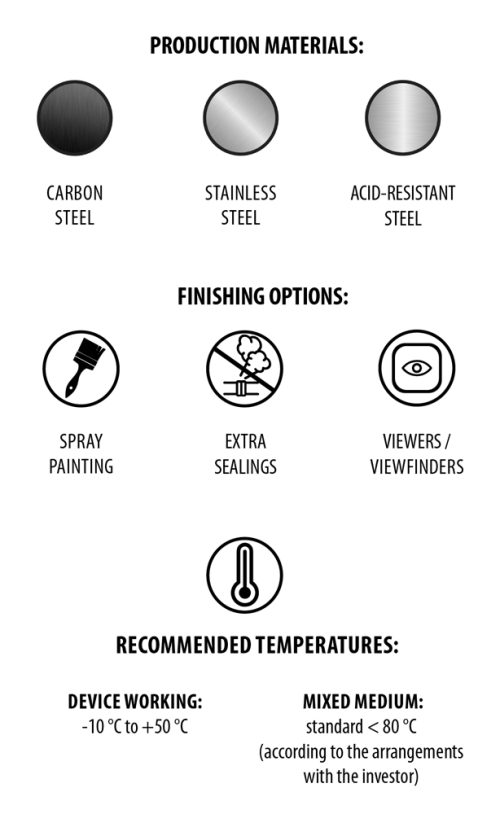

The combination of high-quality materials and simple construction results in reliability. Screw mixers made of stainless steel are resistant to corrosive factors, making them durable and long-lasting. For demanding transport processes of semi-finished products or abrasive raw materials, the screw coils are made of steel with increased abrasion resistance, e.g. hardox steel.

An additional advantage of screw mixers is the simplicity of their installation, the ability to work in difficult conditions and low operating costs. We produce screw mixers only from high-quality materials. We offer a wide range of sizes and designs, which allows us to meet the needs of almost every industry. Thanks to our experience and knowledge, we can help you find the perfect solution for your production and industrial installation.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.