Storing dry bulk materials in silos and storage tanks is challenging because the “empty” space just above the stored product in the silo – known as the expansion space – often suffers from condensation problems.

Condensation may be caused by humid transport air, lack of silo insulation, fluctuations in external temperature, general external humidity levels and the hygroscopic properties of the materials stored in the silo.

This becomes a problem because excessive moisture inside the silo not only increases the risk of material spoilage due to increased bacterial growth, but also makes it difficult to empty storage tanks.

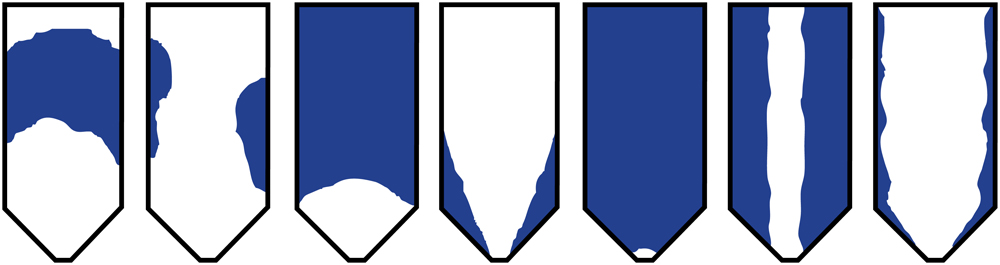

Material sticking to the sides of the silo, in extreme cases called “ratholing”, blocking the silo discharge, clumping, plugging, hanging or bridging the silo load are the most common cases of inability to empty the transport tank.

Material sticking to the sides of the silo, in extreme cases called “ratholing”, blocking the silo discharge, clumping, plugging, hanging or bridging the silo load are the most common cases of inability to empty the transport tank.

There are many hygroscopic materials used in industry, so cases where emptying silos becomes problematic are very common. Examples of such substances include: ammonium sulfate, baking powder, calcium phosphate, caustic soda, cocoa, coffee concrete, corn sugar, dextrose, salt, flour, gelatin, gypsum, lime and others.

There are many hygroscopic materials used in industry, so cases where emptying silos becomes problematic are very common. Examples of such substances include: ammonium sulfate, baking powder, calcium phosphate, caustic soda, cocoa, coffee concrete, corn sugar, dextrose, salt, flour, gelatin, gypsum, lime and others.

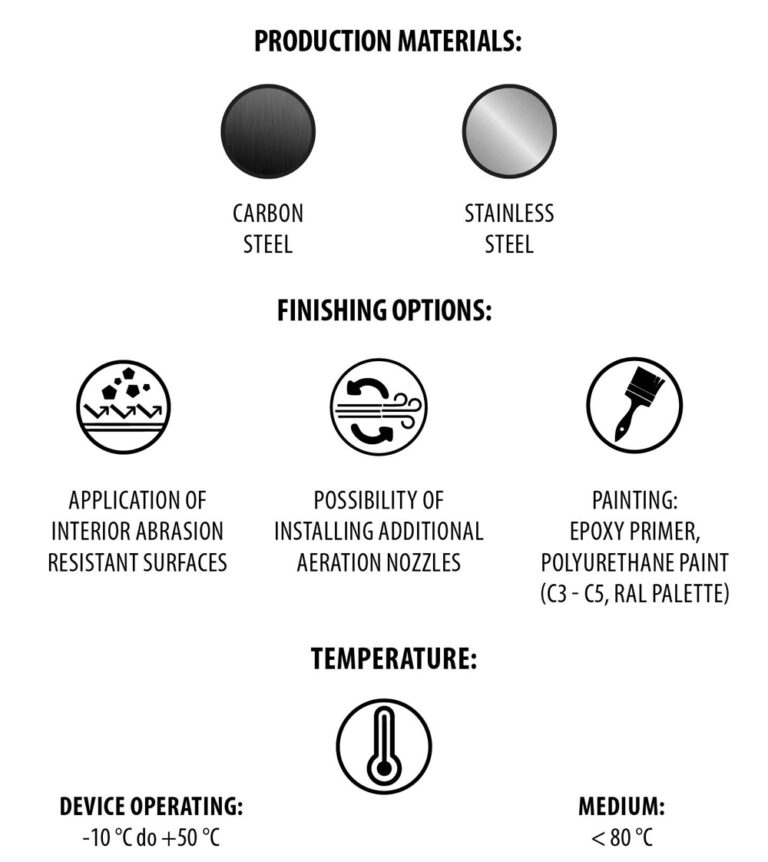

To minimize the impact of product accumulation, all types of mechanical deagglomerators are used, as well as vibrating bottoms equipped with special motovibrators or vibrating hammers. It is possible to install an additional fluidization/aeration system for the material. The use of additional aeration nozzles on the vibrating bottom cone is recommended especially during longer technological breaks when the material needs to be deaerated and in the case of powdered materials such as flour, lime, gypsum or hydrated lime.

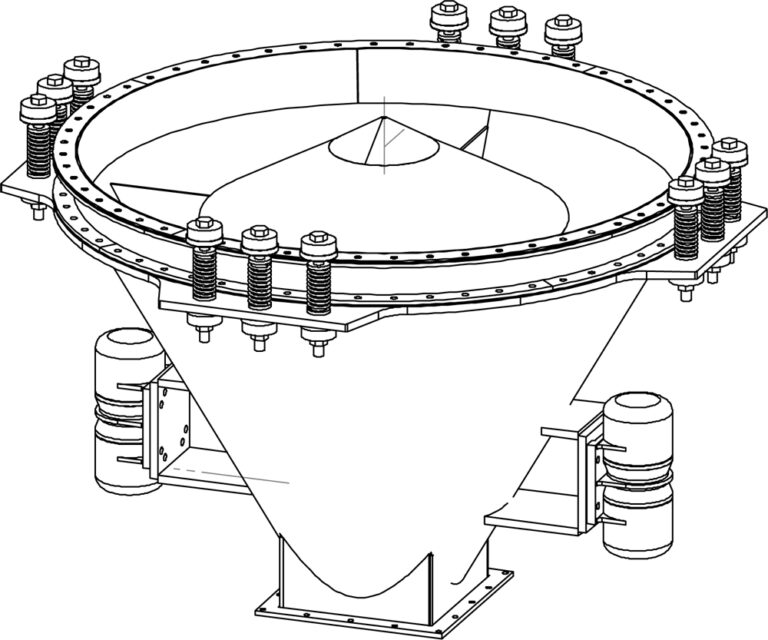

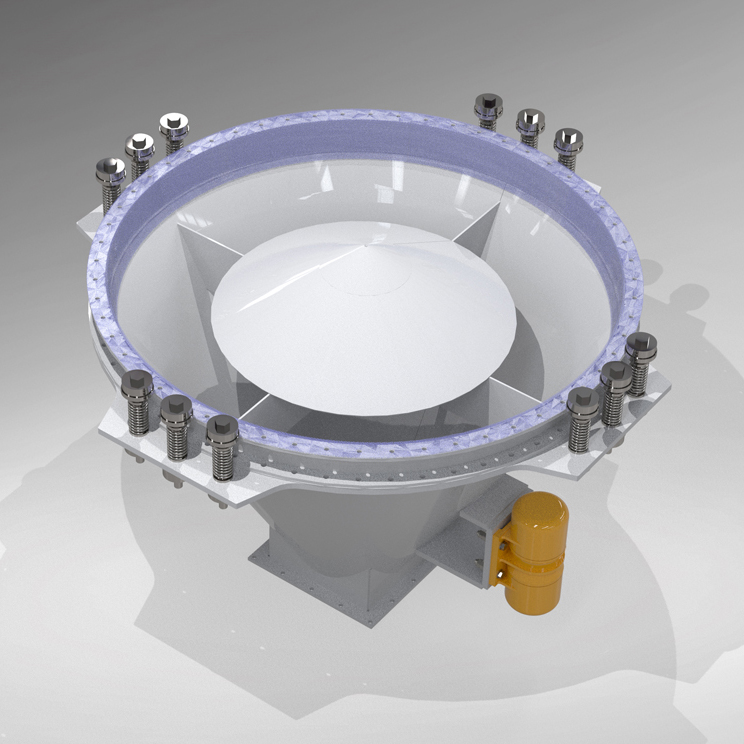

Vibrating bottoms produced by Biko Tech are semi-convex, semi-conical devices. When placed in a state of vibration, they facilitate the emptying and flow of material from empty baskets and transport tanks or storage silos. Vibrating bottoms are used for specific applications, especially in the food industry (especially in the field of grinding), and to facilitate the discharge of material in the form of powder or granules. The use of this device ensures optimal emptying of the storage tank, creating a “mass flow” situation inside the silo, thus avoiding the phenomenon of concentration and blocking of the material discharge. The hopper, through its vibration, changes the resting friction of material particles between themselves and between the cone of the vibrating bottom to much smaller and more sliding. In the vast majority of cases, this is sufficient to ensure laminar flow of material from the silo and enable its unloading.

Motovibrators and vibrating hammers mounted on the cone generate vibrations in the vibrating bottom each time the feeding device, located under the silo, is activated to extract material. During operation, the active bottom creates a conical (rotational) motion that is transferred to the material in the silo. The result is an unimpeded flow of material through the bottom outlet to connect to any type of conveyor. Unique design features ensure Biko Tech vibrating cones completely safe operation throughout the entire time of use.

In order to install the collecting bottom, the silo cone should be shorter than standard and equipped with a flange. The flange is delivered before the vibrating bottom is delivered or together with the selecting bottom. It is welded to the silo at the assembly site.

Special slings and a compensator create a flexible connection between the silo and the vibrating bottom. The compensator (sealing collar) connecting the vibrating bottom with the fixed part of the vertical silo, and the connection between the discharge from the vibrating bottom and the receiving device, are made of two-layer aramid fabric, and for the food industry, optionally, of white neoprene or silicone.